How glass bubbles can reduce the weight of TPO parts

As the search continues for lower material costs, without sacrificing performance or processability, glass bubbles are getting more attention. Reducing density with additives is not new, but bubbles are showing advantages. (Contributed by 3M, edited by IMM Staff)

September 3, 2010

As the search continues for lower material costs, without sacrificing performance or processability, glass bubbles are getting more attention. Reducing density with additives is not new, but bubbles are showing advantages. (Contributed by 3M, edited by IMM Staff)

Resin compounder Noble Polymers (Grand Rapids, MI), a subsidiary of manufacturer Cascade Engineering, has developed a low-density resin formulation that reduces the weight of parts molded of TPO (thermoplastic polyolefin) by up to 20%. It’s a masterbatch bulk resin additive that incorporates hollow glass bubbles from 3M Co. to displace resin and reduce part density in molded, thermoformed, and extruded products.

|

“Mandated standards for Corporate Average Fuel Economy (CAFE), along with the drive to reduce industrial emissions and achieve more sustainable production methods, have led to a growing demand for enhanced TPO production methods,” says Tim Patterson, Noble Polymers business unit manager. “Glass bubble additives in our masterbatch material displace hydrocarbon-based resin content and lighten parts to help cut transport fuel consumption.

“Use of density-reducing agents for filled TPO raw material is not a new concept,” Patterson continues. “While various filler materials have been used to reduce TPO part density, glass bubbles have significant process and resin displacement advantages over alternate fillers. We’ve found that the addition of glass bubbles yields secondary benefits to TPO components as well, including improved part stiffness, greater dimensional stability, and reduced shrinkage.”

Patterson says traditional resin-displacement mineral fillers such as cenospheres, asbestos particulate, chopped glass fiber, and calcium carbonate (CaCO3) have considerably less volume per unit weight than glass bubbles. For example, 1 kg of typical glass bubble material has a volume of 1666.7 cm3, while the equivalent weight of CaCO3 displaces only 370.4 cm3. Thus its resin displacement potential per unit of weight is only a fraction of that of glass bubbles.

Glass microspheres

Hollow glass bubble technology was developed by 3M in the 1960s, and today is used in aerospace and military systems, paints and coatings, marine hulls, oil and gas exploration and production, and more. 3M senior product development specialist Steve Amos of the Energy & Advanced Materials Div. laboratory explains that 3M glass bubbles are made from a chemically stable soda-lime borosilicate glass, produced in a range of properties, and include nominal diameters from 9-70 µm, densities from 0.15-0.60 g/cm3, and compressive strength ratings from 250-30,000 psi.

|

Noble Polymers materials engineer Bo Wang says 3M and Noble collaborated on resin masterbatch developments for a number of months, with the glass bubble supplier contributing to feedscrew design and porting refinements, and recommending process variables to help ensure bubble survivability during formulation and TPO production. 3M also assisted Noble with information about loading levels, and conducted quality tests to measure and confirm bubble survival in molding and extrusion processes.

Glass bubble selection

Wang says the class of bubbles selected for a masterbatch depends on the end use of the TPO component. For example, the pressures involved in TPO molding require glass bubbles with elevated crush strength, such as 3M’s iM30K product, rated at 30,000 psi. Glass bubble strength is generally proportional to density, and thus lower-strength bubbles are less dense, and offer greater potential for TPO weight reduction than thicker-walled, higher-strength bubbles.

According to Wang, bubble size impacts TPO surface finish as well as stress transmission through the composite, with smaller bubbles contributing to more favorable impact and tensile properties. “In general, higher-strength bubbles are required for injected molded interior and exterior automotive components, and other industrial components,” says Wang.

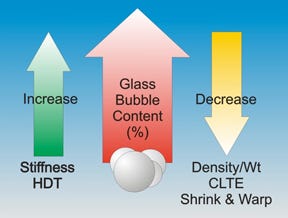

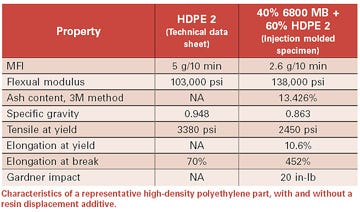

Noble’s development work shows that mold shrinkage in a TPO part is inversely proportional to the volume percentage of glass bubbles in the mix. The modulus (stiffness) of a part also increases in proportion to the ratio of glass bubbles to resin. The positive attributes of increased stiffness and heat distortion temperature (HDT) as well as decreasing coefficient of linear thermal expansion (CLTE), shrink, warp, and sink marks continue to improve as the percentage of glass bubbles in the resin mix rises. Tensile strength, elongation, and impact strength tend to decrease as well. Complementary additives in the masterbatch can modify these values to some degree.

“In general, plastics are flexible and experience ductile failure under stress, while glass adds stiffness but is more prone to brittle breakage,” said Wang. “It is possible to improve TPO impact strength by adding an impact modifier to the masterbatch that reduces potential for brittle failure while maintaining the stiffness advantage.”

According to Wang, the concentration of glass bubbles in a masterbatch additive mix varies, but can be as much as 50% by weight, depending on customer requirements. Finished parts made using this masterbatch glass bubble concentration will be 20% or more lighter than resin-only parts.

“Process tests show that a Noble masterbatch formulation with glass bubbles can cut TPO injection molding production time as much as 20%,” says Wang. “This benefit is apparently related to changes in thermal properties that result from displacing resin with hollow glass (reduced mass), and the resulting time savings are concentrated primarily during the cooling period.”

In addition to automotive, 3M is exploring markets such as building materials, composite materials, sporting goods, and construction applications, where benefits seen include weight reduction, processing improvements, and product design enhancements, according to William Donahue, business manager, Resin System Additives, 3M Energy & Advanced Materials Div.

And the cost compared with straight TPO? “There is a premium that can be offset by manufacturing improvements, weight reduction, and/or product enhancements,” says Donahue. “The potential cost savings depends upon the density and the cost of the polymer.”

Noble Polymers works with individual customers to determine precise TPO part specifications, and multiple interests are weighted in a staged/gate process to achieve optimum density reduction while meeting necessary physical specifications. The resulting formulas are confidential and proprietary to customers. Patterson estimates that nearly half of the company’s TPO masterbatch customer applications call for some degree of formula customization, while the balance can be met using the company’s standard masterbatch material.

An automaker tests the bubbles

In 2007, the Hyundai Mobis IP Core Part Development Project finished a 19-month series of tests comparing a PC/ABS material with a new PP material filled with 3M Glass Bubbles iM30K. “We were exploring new material formulations that would help reduce overall part weight and costs in the production of instrument panel core parts,” says S. Ka, research engineer for the Cockpit Module Design Project. He says that using the PP material with glass bubbles achieved a 16.8% reduction in weight, and lowered the finished part cost by a solid 50% (cost of materials in Korea), compared with the same cores made in PC/ABS. “In addition, we experienced improved material flowability and better dimensional stability compared to current talc-filled polypropylene.” The change allowed the use of existing tooling, so no capital outlay there, and also reduced part warpage. —[email protected]

Want the real numbers? Download three PDFs from 3M to aid your research:

• Guidelines on how to mold with 3M glass microspheres.

• Case study on how Hyundai achieved a 16.8% weight reduction and 50% lower part cost using PP with the microsphere vs. PC/ABS.

• Cycle time savings achieved in a cabin air filter frame.

About the Author(s)

You May Also Like