Is a hot runner worth the cost for your customer? Do the math!

Just like other consumers the world over, injection molders’ customers hate to pay for things they don’t need. That is fair enough, but problems arise when a molder believes an item is necessary and his customer disagrees.

April 22, 2009

Just like other consumers the world over, injection molders’ customers hate to pay for things they don’t need. That is fair enough, but problems arise when a molder believes an item is necessary and his customer disagrees.

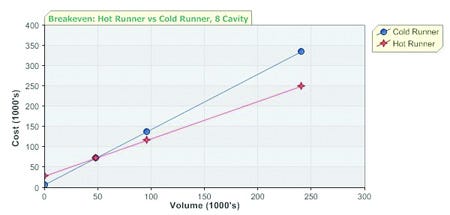

Hot runners are one such source of strife. They add to the cost of a mold, without question. They also help save material, among other benefits, so it’s never been too hard to justify the added expense of a hot runner-equipped mold to a customer in need of millions of parts—in packaging applications, for instance. But more frequently in question is whether a hot runner makes sense for low- or mid-volume molding projects.

|

To support processors’ arguments in favor of hot runner use, and clearly also to help its own sales effort, hot runner manufacturer Mold-Masters (Georgetown, Ontario) has developed a Hot Runner Justification Tool, which is available on its website. Only three basic inputs are needed for the tool to yield a cost comparison trade-off for both hot runners and cold runners for a range of mold cavitations. Those in need of a more customized calculation can choose an advanced option with multiple inputs. —[email protected]

About the Author(s)

You May Also Like