New blister packer for pharmaceutical traceability at dispensing unit level

At the upcoming ACHEMA 2015, the trade show for the process industries taking place this year from 15-19 June in Frankfurt/Main, the Germany-based manufacturer of packaging and processing solutions Romaco Group will show end-to-end solutions for granulation and coating, tableting and primary and secondary packaging. Among the novelties on show: a new blister line with an integrated anti-counterfeiting system, enabling the primary packaging to be unequivocally identified, which Romaco is unveiling at the show.

April 30, 2015

At the upcoming ACHEMA 2015, the trade show for the process industries taking place this year from 15-19 June in Frankfurt/Main, the Germany-based manufacturer of packaging and processing solutions Romaco Group will show end-to-end solutions for granulation and coating, tableting and primary and secondary packaging. Among the novelties on show: a new blister line with an integrated anti-counterfeiting system, enabling the primary packaging to be unequivocally identified, which Romaco is unveiling at the show.

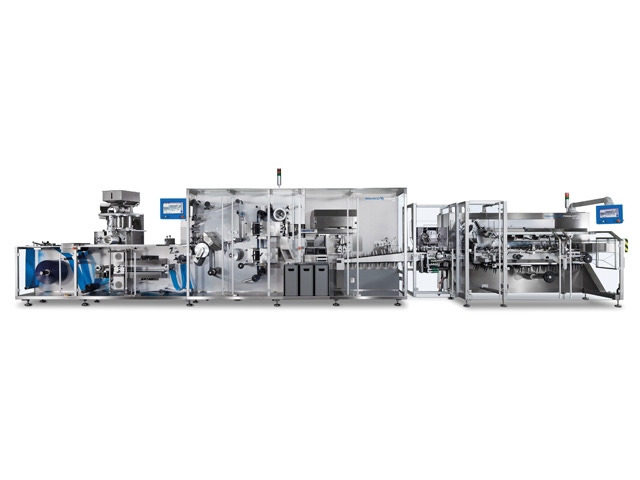

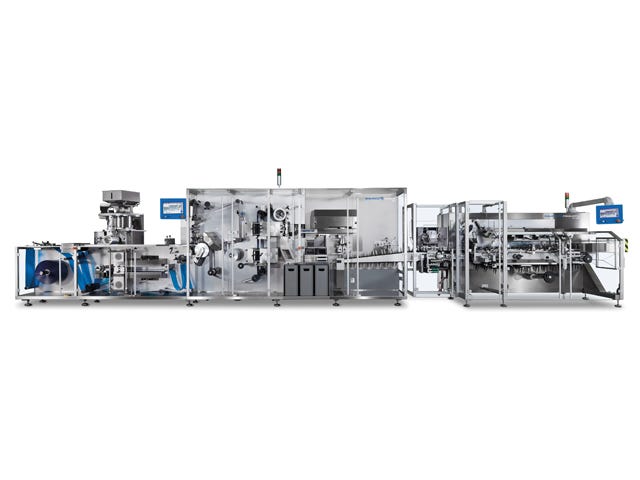

The innovative Noack 960 blister packer combines the latest in servo technology with advanced robotic product handling systems to achieve the highest system availability and overall equipment efficiency or OEE values on the market today, according to the company.

The innovative Noack 960 blister packer combines the latest in servo technology with advanced robotic product handling systems to achieve the highest system availability and overall equipment efficiency or OEE values on the market today, according to the company.

The newest Noack 960 blister solution now comes with integrated anti-counterfeiting system for pharmaceuticals, featuring new technology that was developed in an exclusive partnership with the Swiss-German product authentication and fraud protection specialist NANO 4 U. Their technologies are based on the nano-structuring of product- or packaging surfaces, to which embossed optical properties and multilayer security features are added, such as machine-readable covert or overt coding.

The technology meets all the requirements of the EU's Falsified Medicines Directive 2011/62/EU. A unique stamped hologram, which identifies each blister unequivocally, provides proof of originality at dispensing unit level. This cGMP compliant blister system built by Romaco Noack additionally offers short cleaning times, quick format changes and an advanced level of automation. The Noack 960 blister machine is supplied with rotary or platen sealing and packs pharmaceutical solids in a variety of shapes and sizes. The interchangeable QuickFeed unit enables parallel operating steps instead of sequential. Thanks to the patented technology, product changes are completed in less than thirty minutes.

The blister machines in the Noack 900 range can be integrated with either continuous or intermittent horizontal cartoners from the Promatic PC 4000 series to form a highly efficient system. The two machine ranges are optimally harmonized and simple to operate thanks to their shared design architecture. They can be readily integrated into a variety of blister system configurations.

The new Noack 960 blister system on display at the ACHEMA show will be installed in an in-line configuration with the Romaco Promatic PC 4000 continuous motion cartoner and deliver a maximum output of 700 blisters and 420 cartons a minute.

About the Author(s)

You May Also Like