Plastic machinery suppliers embrace one-stop shop concept

One-stop shop is such a catchy term. Walmart clearly pushes this concept, which is said to make consumers spend more. Amazon Prime takes it one step further and offers free shipping, giving users the freedom to order goods in their pajamas.It makes sense why we're naturally drawn to the idea of a one-stop shop. Time is precious and if we can get all our "shopping" done in one place, it's hard to deny the appeal.

December 30, 2014

One-stop shop is such a catchy term. Walmart clearly pushes this concept, which is said to make consumers spend more. Amazon Prime takes it one step further and offers free shipping, giving users the freedom to order goods in their pajamas.

It makes sense why we're naturally drawn to the idea of a one-stop shop. Time is precious and if we can get all our "shopping" done in one place, it's hard to deny the appeal.

But one-stop shop is not limited to business-to-consumer companies. After years of consolidation, several plastic machinery suppliers have gone the route of one-stop shop to gain a competitive advantage.

PlasticsToday checked in with three big players in machinery to get a gauge for the concept.

No. 1 concept in the plastics industry?

No. 1 concept in the plastics industry?

Combining a robot and auxiliary maker with an injection molding press caused a bit of a stir, but the bet is paying off for Wittmann Battenfeld, said Sonny Morneault, national sales manager for Wittmann Battenfeld USA.

"When Dr. Wittmann purchased Battenfeld, many of us were baffled, but seven years later we can easily understand his vision and foresight," he said. "The major difference between Wittmann Battenfeld and all the other machine suppliers is that they are not offering products and services that they own. Most are an OEM product from a partner supplier. We all know the problems and finger pointing that happen with that business model."

Morneault believes that the one-stop shop concept is the "number one trend in the plastics industry." But how is it actually conducted? Morneault describes the process.

"Let's say you were thinking about getting into plastic molding. You'll need a molding machine - we have that - possibly a robot and automation to compete in today's market - we have that - a water temperature controller - we have that. Of course, you'll need some way to get the plastic pellets to the press - we have that. You may need to dry, blend, or feed those pellets - we have all those. And last but not least, you'll need a grinder to dispose of or reuse your wasted plastic -yes, we have that."

"Another important note is that, because we are the manufacturer of all this equipment, making [the systems] communicate and integrate with each other is easy," adds Morneault. "We are saving our clients time and money, because they won't have to do this once the equipment is delivered."

Some other points of the one-stop shop concept: single POs; billing from one source; delivery updates from one source; collaborative engineering, project management supplied by Wittmann Battenfeld; service and parts from one supplier, special bundle pricing (the more you buy, the more you save).

"We recently sold a large multi-national company multiples of all the products I noted above," Morneault said. "When I asked the purchasing manager what was the deciding factor to go with us, he said, 'Sonny, anything I need for my plant I know I just have to call you, saving me time from calling numerous suppliers and getting multiple bids.' Of course, the terms of the sales including special pricing were all worked out prior to his statement."

Still, quality can be perceived as a drawback of the one-stop shop concept. By offering various technologies and services, potential customers could be hesitant that each offering is truly up to the same high standard. However, Morneault says that is not an issue.

"This is the one area we pride ourselves," he said. "All of our products not only have to live up to high quality standards, they also must have the best ergonomics and user friendliness, and they all have a niche technology that sets us apart from all other suppliers."

Morneault said that clients not having to add staff to handle equipment upgrades or additions result in substantial savings. And at the same time, offering the one-stop shop concept has actually spurred demand for new positions within his company, including more project managers, inside sales and support staff.

"One of these positions we created we call 'multiline project manager,'" he said. "They will manage any project that includes a molding machine and any other auxiliaries."

Meshing all components of a manufacturing cell

Sterling Manufacturing Co. of Lancaster, MA, has almost doubled in growth since its ownership change in mid-2011. To what do they attribute this growth? Because they invest in new technology, whether it is a new injection molding machine, innovative processing technology, integrated automation, or the latest in 3D printers.

One of its first, and major, partners in new technology is Engel, Sterling's exclusive machinery and automation supplier. In fact, owner John Gravelle refers to Engel as its "one-stop shop."

"We can turn to Engel for small or large tonnage machines; horizontal or vertical; for hybrids, all-electrics, tie bar-less, and two-shot presses," states Gravelle. "On top of its large product portfolio, the company also provides built-in automation and specialty options that allow us to customize our presses to suit the needs of our business."

Mark Sankovitch, president of Engel North America, said that the company wholeheartedly embraces the one-stop shop concept.

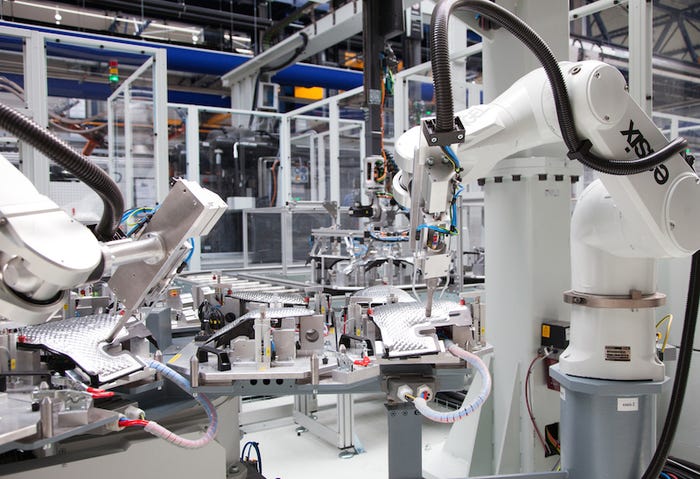

"The percentage of system solutions is continuously increasing in our order books," he said. "Our understanding of a system solution is a turnkey production cell that is supplied from a single source and individually tailored to the requirements of the project."

Engel has developed from an injection molding machine manufacturer to

a system provider, he said. A key driver of this development is that requirements are becoming increasingly complex. Low unit costs, productivity, efficiency, and sustainability can only be combined if

all components of a manufacturing cell mesh in the best possible way. This helps Engel to increase the competitiveness of its customers.

Another advantage for its customers? The single point of contact for the entire project right from the outset, rather than needing to coordinate many different suppliers themselves. Sankovitch says that this saves much time and effort, especially during the project planning phase, and it also accelerates the startup and service calls. As a general contractor, Engel has overall responsibility, and this includes system components that are realized in collaboration with partner companies.

Engel works to offer homogenous, highly integrated and automated system solutions worldwide from a single source. In addition to the injection molding machine, robots, and automation solutions, this can also include the individual process technologies, the mold, other peripherals, and training and service for the complete system, Sankovitch said.

"It is important that, in doing so, we focus our attention on the human/machine interface," Sankovitch said. "As the level of integration and automation increases, the manufacturing process becomes more complex. Yet, in order to be able to control it efficiently and safely, you need clear-cut, intuitive controls. This is why our Engel system solutions fully integrate the robot's control unit into the injection molding machine's control unit. This means that the operator does not need to learn two different systems of operating logic, but can set and monitor all relevant parameters for the overall process, both on the machine and robot display."

Sankovitch said that the injection molding machines in the company's system solutions, like many of the robots and process technologies, are of the company's own design and manufacture.

"In addition to this, we collaborate with system partners who are leaders in their fields. This helps us ensure that we offer our customers the best technologies available in the world. Each manufacturing cell is individually tailored. We take into account the requirements of the product, the local conditions, and the specific industry trends. Through consistent alignment and focus within our business units, we know and understand the requirements of our customers very well. The industry experts in our business units combine their experience from worldwide projects and collaborate very closely with our sales offices."

Support from pellet to finished part

In 2013, Milacron generated lots of attention when it completed the acquisition of Mold-Masters. With that acquisition, Milacron's combined enterprise featured: Milacron Plastics Machinery (injection, structural foam, extrusion, and blowmolding machines); Mold-Masters (hot runners); DME Company (mold technologies); Aftermarket (parts and service); and CIMCOOL Fluid Technology (metalworking fluids and services).

In 2014, Milacron completed the acquisition of Industrial Machine Sales, Inc. (IMSI) and its sister company, Precise Plastics Machinery (PPM). IMSI specializes in the application engineering of primary plastics processing and support systems for many operations, including injection molding, extrusion and blowmolding.

In 2014, Milacron completed the acquisition of Industrial Machine Sales, Inc. (IMSI) and its sister company, Precise Plastics Machinery (PPM). IMSI specializes in the application engineering of primary plastics processing and support systems for many operations, including injection molding, extrusion and blowmolding.

In addition, Milacron, combining

the collective technologies of Uniloy, Mold-Masters, Kortec, and DME, has launched a partnership with Big 3 Precision Molds. This agreement brings together the development and commercialization of technologies in the injection blowmolding sector. The partnership features a technical center that will allow Milacron and Big 3 to work closely with customers for the development of injection blowmolding systems, both for monolayer and co-injection applications.

The technical center will be located at Big 3 Precision's Millville, NJ, facility. In addition to the moldmaking capabilities, the partnership will provide a GMP- certified, climate-controlled lab with two Uniloy injection blowmolding machines.

"We clearly see and recognize the customers' desire for a complete service provider and a partner with expertise from the design of the machine to the different materials complexity to the molding operations," said Shawn Reilley, Group VP of sales and marketing for Milacron. "We believe that in North America, Milacron offers the largest field service organization with over a hundred core technicians in the field, the largest part inventory in the industry, and we operate on a seven-day basis supporting customers."

Milacron provides support from plastic pellet to finished part and everything in-between.

"We believe that the chain of product offerings is only as strong as the weakest link," Reilley said. "Quality and continuous improvement is a daily factor here at Milacron."

About the Author(s)

You May Also Like