Polypropylene intake manifolds solve multiple challenges, acoustically superior to polyamide

With intake manifolds made of polypropylene (PP), Röchling Automotive (Mannheim, Germany) says it has set new benchmarks in terms of cost, weight, and acoustics. These three criteria have been improved due to the lower density of polypropylene (PP) compared with polyamide (PA), the material currently most widely used for intake manifolds.

May 16, 2012

With intake manifolds made of polypropylene (PP), Röchling Automotive (Mannheim, Germany) says it has set new benchmarks in terms of cost, weight, and acoustics. These three criteria have been improved due to the lower density of polypropylene (PP) compared with polyamide (PA), the material currently most widely used for intake manifolds.

|

Raw-air intake with resonator, air-filter housing with air filter, plus intake manifold with throttle flange comprise the complete intake manifold system in VW's 1.0-L three-cylinder engine. |

|

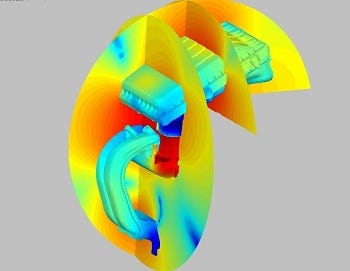

The acoustic problem zone between the air-filter housing and intake manifold shown in red. A PP-based system reduces sound pressure by 10 to 15 dB, which is one of the key selection criteria over PA. |

At the same time, PP is said to offer sufficient sturdiness. Two reference engines from VW that employ PP are the one-liter three-cylinder petrol engine in Brazil and Europe and the 1.6-liter, four-cylinder petrol engine in China.

"The PP intake manifold is the first and only one of its kind in China and Brazil to date. It's also the first three-cylinder application in Europe, and particularly demanding in terms of acoustics," says Marco Barbolini, product manager for the air intake system at Röchling Automotive. "These are Röchling's first intake manifold applications using polypropylene. To be able to substitute for polyamide, there were a number of challenges to overcome. But we were rewarded with improved acoustics."

The 15% cost advantage over PA is made possible by the need for fewer processing steps plus the lower melting temperature and density. Moreover, PP is easy to obtain worldwide. "We have found a local PP supplier in each of the target markets," reports Barbolini. Since PP does not need drying and the tooling and melting temperatures are lower, the manufacture of the components is less energy-intensive. This has the added benefit of reducing the carbon footprint according to the processor.

In spite of the lower processing temperature, Röchling now attains almost the same continuous operating temperature of 120 degrees with PP as with PA. However the PP does require special heat stabilization, above all because of the crucial hot-air resistance requirement. "This is where our particular expertise comes in," says Barbolini. Further, PP and PA have the same rigidity at room temperature and low temperatures.

The weight advantage of 15% over PA entails no disadvantages in terms of tensile strength and stretch at break. The most important mechanical properties are sufficient for requirements, even if they are not always on a par with those of polyamide. PP is also stable with regard to chemical resistance. In terms of ethanol resistance, it is even superior to PA, and moisture absorption properties are also better.

Superior sound

The lower density also results in acoustic emissions that are superior to PA—"measurably and audibly" so, according to VW—in particular at higher engine speeds and frequencies, where the sound pressure is as much as 10 to 15 dB lower. This superior acoustics comfort was ultimately also the reason for substituting PA with PP. The geometry of the intake manifold only had to be adapted very slightly to achieve the same rigidity values with the new material.

Röchling Automotive carried out the complete modification development and applied acoustic design principles to the complete air intake system, paying particular attention to the air filter housing. This involved simulating the acoustic effects of various sizes and shapes of anchorage points, decoupling elements, the top and bottom of the air filter housing, intake manifold plenum and throttle flange. The degree of correlation between calculated and measured values was satisfactory.

The geometry, material, density and sealing of the filter itself likewise affect the acoustics. The acoustic technicians benefited from the fact that the air filter with its muffling effect was also developed and manufactured in-house. This meant that the acoustics of the complete module of intake manifold and air filter housing could be optimized as a single system. —[email protected]

About the Author(s)

You May Also Like