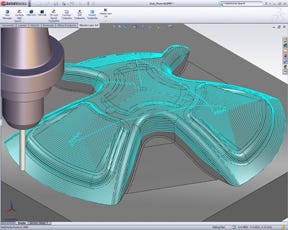

Seamless CAD-CAM connection

Another CAM software supplier now offers seamless integration of its software offering with the SolidWorks CAD package. Mastercam X4 for SolidWorks from CNC Software Inc. (Tolland, CT) enables direct programming of tools within SolidWorks. It provides a full suite of cutting strategies, including Feature Based Machining (FBM) and 3D High Speed Machining (HSM) toolpaths.

February 10, 2010

Another CAM software supplier now offers seamless integration of its software offering with the SolidWorks CAD package. Mastercam X4 for SolidWorks from CNC Software Inc. (Tolland, CT) enables direct programming of tools within SolidWorks. It provides a full suite of cutting strategies, including Feature Based Machining (FBM) and 3D High Speed Machining (HSM) toolpaths. The package also delivers a powerful set of automated cleanup toolpaths, enabling toolmakers to get their molds off the machine faster and with little or no handwork, according to its maker.

|

Mastercam for SolidWorks reportedly offers many benefits to both the Mastercam and SolidWorks communities alike. It relies on familiar, shop-tested parameter screens and processes, and presents a machining tree that provides quick access to any point in the machining process. High-power machining functions include Dynamic Milling, which creates a constantly adapting toolpath that delivers more consistent cutting conditions and allows use of the entire tool flute length, High Speed Machining, and Peel Milling to ensure efficient constant climb milling between two selected contours or along a single contour. When cutting hardened material, the peel mill toolpath allows the toolmaker to use the full flute depth of the cutter and avoid taking many shallow cuts. —[email protected]

About the Author(s)

You May Also Like