Easier operation, more performance, lower costs Brückner’s theme at K 2016

July 26, 2016

Brückner Group has announced that it will be showing a host of new machines, services and systems at the upcoming K Show in Düsseldorf, Germany. Pride of place, says the company, will be reserved for the new “intelligent line management” (ILM), developed in response to the increasing challenges confronting film producers and their operating personnel stand when it comes to guaranteeing a stable and efficient production with the highest quality film.

Brückner Group has announced that it will be showing a host of new machines, services and systems at the upcoming K Show in Düsseldorf, Germany. Pride of place, says the company, will be reserved for the new “intelligent line management” (ILM), developed in response to the increasing challenges confronting film producers and their operating personnel stand when it comes to guaranteeing a stable and efficient production with the highest quality film.

The new ILM system is being touted as an integrated solution designed to smooth customers’ transition towards “Smart Production” and “Industry 4.0”. The focus is on the process rather than the machine alone, as illustrated by the number of assistant systems and tools, for example, for inline measurements, and for directly influencing important film values such as temperature, haze, molecular orienteering angle, density and porosity, incorporated into the ILM concept. Energy consumption is monitored at all line components by Bruckner’s proprietary “Energy Monitor”.

According to the company, the new system allows for simplified line operation with significantly fewer process parameters to adjust and intuitive user guidance. Additional advantages include a greater transparency and traceability of production data and the targeted inline control of film properties for a consistently high film quality.

Brückner Maschinenbau will moreover be presenting what it says is a world first at the show: a 10.4m concept, which promises to fulfil the demand for higher productivity in BOPET production by delivering around 20% more output capacity, with the proven speeds of up to 515m/min.

The company will also be showcasing its newly designed sliding system for transversely stretched film lines, enabling speed increases from over 600m/min. The new design, plus Brückner’s newly developed lubrication materials which have reduced the need for lubrication by more than 50%, lead to lower operating costs and higher efficiency rates for users. Furthermore, these newly developed lubrication materials are also available for upgrades on current high-performance lines.

A new winder system featuring a winder diameter of 1.8m – up from 1.55m - will allow future Brückner lines to take 40% more winder length, thus increasing line efficiency and reducing waste due to fewer roll changes and overall boosting productivity while lowering changeover time and energy consumption for the entire line. The company has also widened its selection of LISIM (Linear Motor Simultaneous Stretching) lines for BOPA film. At K2016, lines with a working width of 6.6 meters, up from the usual 5.1 meters, will be on display. This increases output by a good 30% and substantially increases productivity, says Brückner Maschinenbau.

Another Group company, service & upgrading specialists Brückner Servtec, will be introducing  several new service offers, including complete upgrading packages for special products, turnkey relocation of complete production lines including modernization or an extended chain and clip service.

several new service offers, including complete upgrading packages for special products, turnkey relocation of complete production lines including modernization or an extended chain and clip service.

Brückner Group’s Swiss member PackSys Global, a leading packaging equipment manufacturer, is presenting a selection of 360° digital printing, new heading and capping systems, a new generation of tube packing machines and hot stamping on the latest equipment.

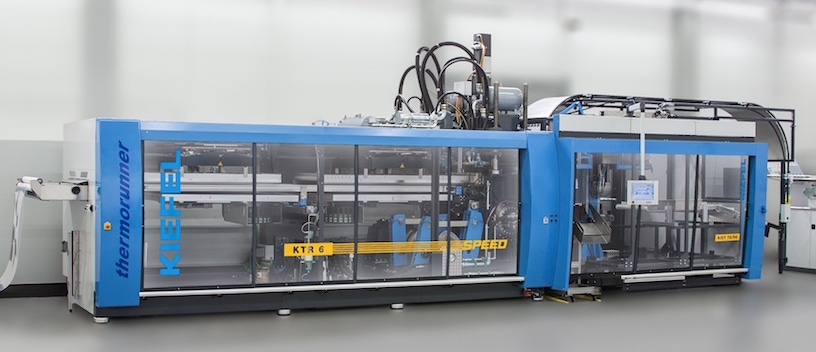

And finally, group member Kiefel will be launching the latest generation of the Thermorunner at K2016. Kiefel’s latest in cup-forming machines - the KTR 6.1 Speed offers a significant rise in punching force - combined with a greater forming area – thus further increasing the number of cavities to produce more cups than ever. The newly developed pre-stretching plug is actuated by a powerful linear motor. Faster pre stretching has a positive effect on material distribution and processing speed. The sophisticated KIST vertical  stacking system works without the assistance of brushes or rubber elements, eliminating friction and ensuring smooth, hygienic production. Domed lids designed to fit these cups are produced on Kiefel’s new Speedformer KMD 78 Power machine. Both machines will be on show at this October’s Düsseldorf K 2016 event.

stacking system works without the assistance of brushes or rubber elements, eliminating friction and ensuring smooth, hygienic production. Domed lids designed to fit these cups are produced on Kiefel’s new Speedformer KMD 78 Power machine. Both machines will be on show at this October’s Düsseldorf K 2016 event.

Kiefel will also be showing a new space-saving benchtop filling module for infusion bags and the latest welding generator with pioneering semiconductor technology, both for the medical sector.

About the Author(s)

You May Also Like