Plant-Derived Phenolic Resin Debuts in Japan

Sumitomo Bakelite’s solid novolac phenolic resin utilizes nonedible lignin as a raw material.

September 8, 2020

Sumitomo Bakelite has developed a solid novolac phenolic resin that utilizes lignin as a raw material and manufactures it on a commercial basis. The company will target auto applications, particularly in electric vehicles, for the new product.

Sumitomo Bakelite is a leading supplier of petroleum-based phenolic resins and it specifically targeted a nonedible plant-based material for its foray into bio-based thermoset plastics.

Lignin is one of the three major components that make up plants along with cellulose and hemicellulose, and it plays a role as a binder to impart physical strength and chemical stability to plant cells. In recent years, lignin, which is a naturally-occurring phenolic polymer, has been used as a renewable resource for heat-resistant aromatic chemicals. Sumitomo Bakelite now plans to use the resource for production of phenolic resin.

|

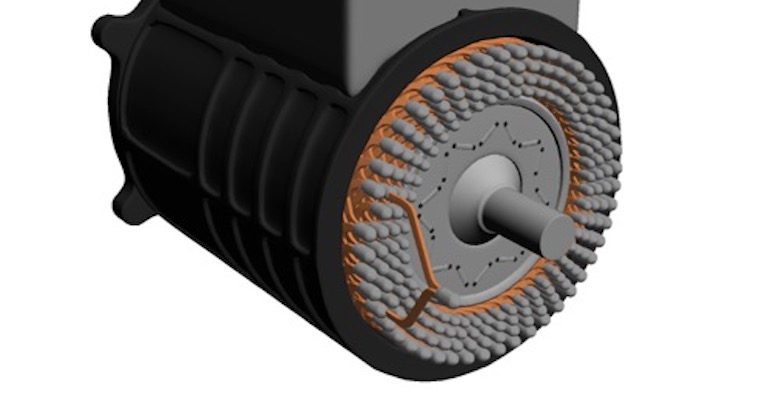

Lignin is used as a raw material for phenolic resin. Image: Sumitomo Bakelite. |

Sumitomo Bakelite has been developing lignin as a raw material for phenolic resin for the past 10 years, in part through participation in government-sponsored R&D projects promoting the use of renewable resources, such as an inedible plant-derived chemicals manufacturing process technology development project running between 2013 and 2019.

Liquid resol-type phenolic resins based on lignin have been applied to wood adhesives mainly in Europe in recent years. Sumitomo Bakelite’s development reportedly presented more challenges in terms of perfecting the production technology, but it has managed to develop a viable process for production of solid novolac-type lignin-modified phenolic resin with a biomass ratio of 50% or more.

About the Author(s)

You May Also Like