Recycling Competition Draws Two Plastic Innovations

Colorado-sponsored contest included recycled “minis” for disc golf and low-cost depolymerization for recycling of textiles.

The state of Colorado is on a mission to improve recycling and composting end markets, and it’s using some show-biz flair to do so. Case in point: The NextCycle Colorado Pitch Competition, a sort of “Shark Tank” for Colorado-based entrepreneurs where nascent recycling-related businesses pitch their ideas to investors.

NextCycle Colorado, a business-accelerator program that supports manufacturing solutions for recycled or recovered content within the state, hosted the 2022 NextCycle Colorado Pitch Competition on June 22, 2022, in Boulder.

Funded by the Colorado Department of Public Health, NextCycle Colorado provides organizations with the resources and expertise needed to take their recycling and composting projects to the next level.

Nine teams participated in NextCycle’s 2022 pitch competition. A competitive application process was used to select the teams, whose ideas ranged from a hyperlocal compost operation to a quarry-waste recycling project.

Two of the teams had particularly intriguing pitches involving plastics: Trash Panda, a start-up that recycles trash into a product used in disc golf; and a duo of scientists from the US Department of Energy’s National Renewable Energy Laboratory (NREL), who are recycling textile waste using a new approach to chemical recycling.

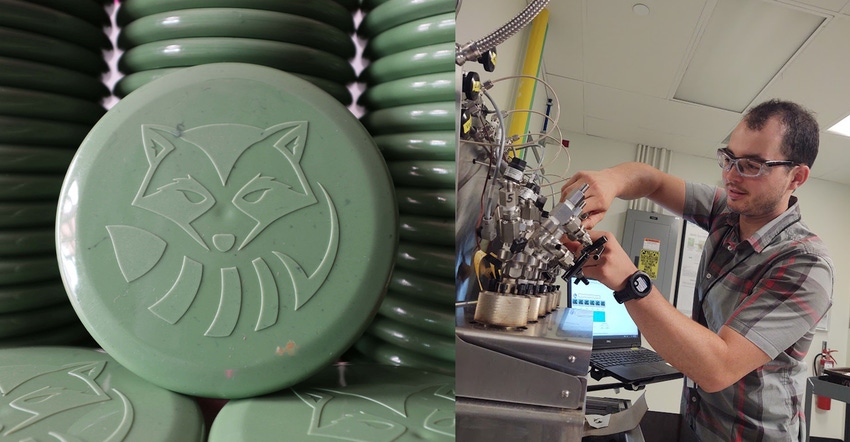

Trash Panda uses recycled plastic to manufacture small discs called minis, which are used as markers in tournament play of disc golf (aka frisbee golf), an increasingly popular sport.

In 2021, Trash Panda launched its first products — 100% recycled high-density polyethylene (HDPE) minis and polypropylene (PP) minis. Trash Panda founder and CEO Jesse Stedman initially produced the discs by hand on an injection molding machine he built in his garage.

By early 2022, the company was able to move its disc manufacturing from Stedman’s garage to the Denver plant of injection molder LTM Plastics. Trash Panda sources its feedstock (plastic regrind) from Denver-based recycler Direct Polymers.

Trash Panda plans a global launch of recycled full-sized discs in October 2022. Stedman expects that within the next five years, his company will be able to divert 200,000 pounds of easy- and hard-to-recycle plastics from landfills annually.

“We plan to make minis out of the most commonly produced plastics in our world, most likely anything from No. 1 to No. 6,” Stedman tells PlasticsToday. "Because Trash Panda’s “minis are not performance-based, our goals are to make the largest impact we can through our production of 100% recycled minis. Currently, our minis [molded by LTM] are made from 100% recycled polypropylene.”

The minis are also recyclable, with the plastic type marked on the bottom of each. They “can be recycled by any recycler who works with that specific plastic type,” Stedman says. “One day we hope to offer our own version of circularity for our products, as well."

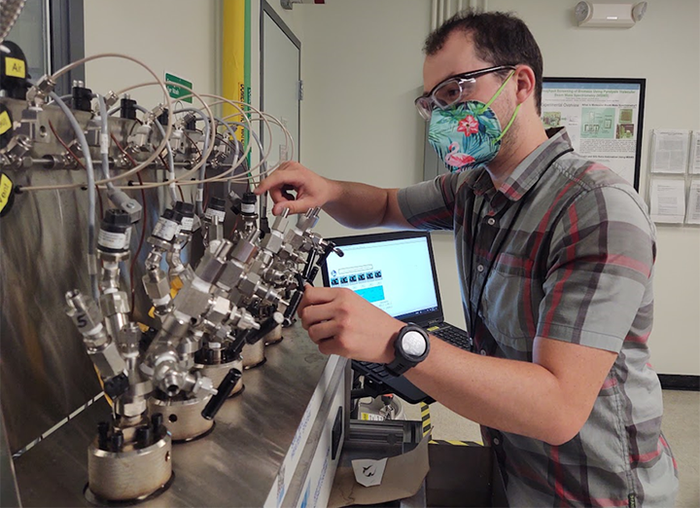

Researchers like Kevin Sullivan seek a pathway to low-energy depolymerization of textiles using abundant catalysts.

Low-cost textile depolymerization at NREL.

A very different pitch, from a two-person team of NREL employees, highlighted a new technology to convert plastic textile waste into usable raw materials for manufacturing.

The technology uses oxidative depolymerization, a form of chemical recycling. The technique can be used to depolymerize mixed plastics, eliminating costly material-separation steps, and is robust to contaminants and additives in textile waste; it has been validated with post-consumer plastics and mixed-composition textiles.

Using metal catalysts and oxygen from the air, the system converts polyesters into their monomeric building blocks. The catalysts are inexpensive, abundant transition metal salts.

The exothermic depolymerization reaction occurs within a relatively mild temperature range — below 230°C/446°F — and requires limited energy inputs. In contrast, current commercial chemical recycling technologies need significant energy inputs, which drives up processing costs and boosts carbon footprint.

Inorganic chemist Kevin Sullivan and organic chemist Mikhail Konev, both postdoctoral researchers at NREL, have been developing the process in the lab for the past three years.

“Our goal is to incorporate a spin-off company within the coming months that will work towards commercialization of this technology in collaboration with NREL, through a cooperative research and development agreement,” Konev says.

“Current efforts are focusing on scaling up the process, performing more detailed techno-economic analysis and life-cycle assessment calculations, and measuring the properties and performance of the recycled materials,” he explains.

Although neither the NREL scientists nor Trash Panda secured investments at the pitch competition, both teams found the experience rewarding.

“We received very positive feedback,” Sullivan says, noting that the competition enabled his team to set up several meetings with venture capitalists. “Many people are interested in finding a practical solution for dealing with textile waste and were excited about our technology.”

Sullivan adds, “I think people resonate with trying to deal with this waste stream. Every second, about a dump truck’s worth of textiles are landfilled or incinerated. That really brings the scale of the problem into perspective.”

About the Author(s)

You May Also Like