UV-curable plastic makes self-healing sensor possible

Sensors that measure the strain or forces exerted on materials in everything from airplanes to civil infrastructure have one vital flaw; they can break under stress rendering themselves useless but not necessarily the material they were monitoring.

June 16, 2011

Sensors that measure the strain or forces exerted on materials in everything from airplanes to civil infrastructure have one vital flaw; they can break under stress rendering themselves useless but not necessarily the material they were monitoring. Researchers from North Carolina State University have overcome this by designing a sensor that can measure strain in structural materials and is capable of healing itself, allowing for continued collection of data that can help determine structural safety in the wake of earthquakes, explosions, or other unexpected events.

Self-healing polymer sensor |

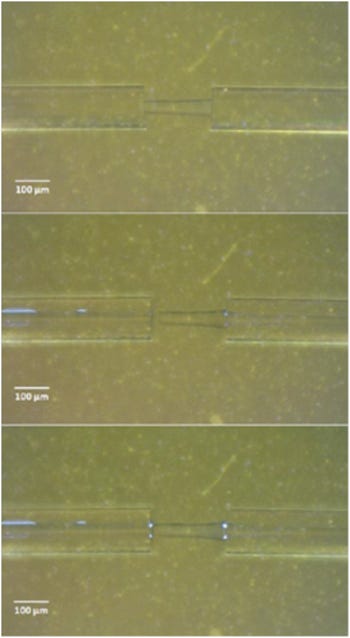

The top image shows the polymer filament connecting the glass fibers in the sensor. The middle image shows where the filament has snapped off. The bottom image shows where the resin has rushed into the gap, been exposed to UV light, and reconnected the filament to repair itself. |

The sensor contains two glass optical fibers that run through a reservoir filled with a ultraviolet (UV)-curable resin. The ends of the glass fibers are aligned with each other, but separated by a small gap. Focused beams of infrared and UV light run through one of the fibers, and when the UV beam hits the resin, the plastic hardens, creating a polymer filament that re-connects the glass fibers and creates a closed circuit for the IR light. The rest of the resin in the reservoir remains in liquid form, surrounding the filament.

The researchers note that the remaining liquid resin is important. If the polymer filament breaks under stress, more resin fills the gap, reacts with the UV beam, and hardens to automatically repair the sensor.

Kara Peters, an associate professor of mechanical and aerospace engineering at NC State and co-author of a paper describing the research, describes the potential application of the new sensors. "Events that can break a sensor, but don't break the structure being monitored, are important," Peters said. "These events could be bird strikes to an airplane wing or earthquake damage to a building. Collecting data on what has happened to these structures can help us make informed decisions about what is safe and what is not. But if those sensors are broken, the data aren't available. Hopefully, this new sensor design will help us collect this sort of data in the future."

The paper, "A self-repairing polymer waveguide sensor," is published in the June issue of Smart Materials And Structures and was co-authored by Peters and NC State Ph.D. student Young Song. The research was funded by the National Science Foundation.

About the Author(s)

You May Also Like