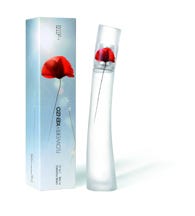

Photorealistic flower through tampo printing

The latest version of the FlowerbyKenzo fragrance is capped by an ingenious, high-resolution flower image captured by Rexam Personal Care (Suresnes, France) via the latest in tampo printing technology. Constant refinement of this process, which in this case involves precise registration of the four colors, has resulted in a fragrance closure that showcases new levels of photographic realism with beautiful contrast and depth, according to Elisabeth Benoît, cosmetic closures sales director, Rexam Personal Care.

August 31, 2009

The latest version of the FlowerbyKenzo fragrance is capped by an ingenious, high-resolution flower image captured by Rexam Personal Care (Suresnes, France) via the latest in tampo printing technology. Constant refinement of this process, which in this case involves precise registration of the four colors, has resulted in a fragrance closure that showcases new levels of photographic realism with beautiful contrast and depth, according to Elisabeth Benoît, cosmetic closures sales director, Rexam Personal Care.

|

“Our team delivered an image resolution of 200 dpi, 25% finer than the standard tampo printing process, for optimal realism and shelf appeal,” Benoît says. “Further, it is important first to master the injection molding and processing of Surlyn [ionomer resin] used for this application, which is preferred by Kenzo’s marketing team for its transparency and fragrance compatibility properties.” Surlyn is supplied by DuPont (Wilmington, DE). Rexam’s Center of Excellence in Simandre, France molded and decorated the Surlyn closure. —[email protected]

About the Author(s)

You May Also Like