Video game software helps designer 3D print jaw implant

A patient in Argentina, in need of an artificial jaw, received a 3D-printed implant that fit perfectly thanks to a design engineer working 5,500 miles away in the Canary Islands with software that is typically used to develop video games. That is the mashed-up world that Belgian industrial designer Sebastiaan Deviaene lives and, by all appearances, thrives in.

October 9, 2015

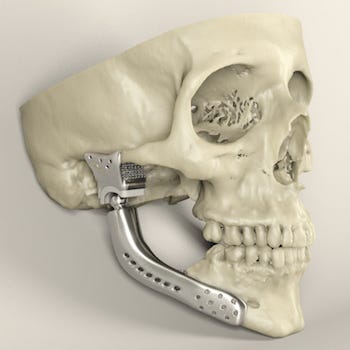

A patient in Argentina, in need of an artificial jaw, received a 3D-printed implant that fit perfectly thanks to a design engineer working 5,500 miles away in the Canary Islands with software that is typically used to develop video games. That is the mashed-up world that Belgian industrial designer Sebastiaan Deviaene lives and, by all appearances, thrives in. He was profiled this week by dezeen magazine in its Future Makers series, a collaborative project with Autodesk that highlights how designers are using digital tools and advanced techniques to push the boundaries of design and manufacturing technology.

|

Image courtesy dezeen. |

Working with the medical engineering department at Instituto Tecnológico de Canarias, a government-funded industrial research and development organization based in the Canary Islands, Deviaene designs custom-fit implants for reconstructive surgery in animals and humans, writes dezeen, an influential magazine and website devoted to architecture and design. He worked with local company Raomed to design the device for the Argentinian patient.

Working from a scan of the patient, Deviaene reconstructed the jawline and produced a 3D-printed implant from medical-grade titanium using electron beam melting technology, by which parts are manufactured in an additive process using melted metal powder. The finished device features a lattice-like structure, where the metal and bone can fuse together, thus stimulating bone regrowth. Deviaene was dissatisfied with the medical modeling software that is available and, instead, used 3DS Max to script the lattice structures and design the custom-fit part of the implant.

"It is funny to use it for medical applications," Deviaene told dezeen, "because it is more of an architectural visualization tool or video game development tool. But it is a very stable platform for mesh-based modeling."

Deviaene plans to apply this technique to the design and printing of implants for softer tissue types in the future. "We are currently testing artificial cartilage in humans—‘hybrids' I call them—where we combine titanium with biocompatible polymers," Deviaene told PlasticsToday. "But we need to wait two years in total before publishing any detailed official news," he said, adding that he and his team are eight months into the project.

Ideally, Deviaene would like to work with bio-absorbable materials, but that adds a whole other layer of complexity, he notes. "For example, you and I probably have different absorption and bone-growth-rates, and even our personal rates will be different within 10 years. So, it is a bit tricky to tackle."

Polymer-based 3D-printed implants also raise the question of recovery time, adds Deviaene. "Once you work on a big injury, you need to take into account the recovery time of the patient. Using polymers, especially bio-absorbable materials, automatically implies a longer recovery time, and, therefore, contradicts the minimally invasive philosophy we try to maintain."

In knee replacement applications, for example, bio-absorbable or biocompatible plastic can't deliver the mechanical support needed, explains Deviaene. "So the patient would need a very close follow-up, monitoring the stage of integration of the implant, with adapted exercises and therapies, scans and so forth. The technical and design limitations and material restrictions are actually small peas compared to the practical approach and implementation of the technology," Deviaene told PlasticsToday.

About the Author(s)

You May Also Like