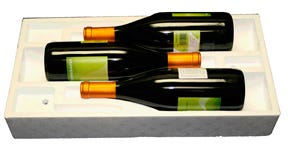

ACH and RAPAC giving EPS a good wrap

ACH Foam Technologies has rolled out its newest packaging, WineLoc wine shipping containers, made from 60% recycled content. WineLoc packaging uses EcoSix, a recycled molding bead manufactured by RAPAC, which offers superior protection, making it one of the most efficient packaging materials for the wine industry, according to ACH Foam (Denver, CO).

June 4, 2010

ACH Foam Technologies has rolled out its newest packaging, WineLoc wine shipping containers, made from 60% recycled content. WineLoc packaging uses EcoSix, a recycled molding bead manufactured by RAPAC, which offers superior protection, making it one of the most efficient packaging materials for the wine industry, according to ACH Foam (Denver, CO).

According to Ken Adams, VP marketing for RAPAC (Oakland, TN), typical EPS packaging has contained either virgin-only material or from 10%-30% recycled content. RAPAC, a Ring Company, is the largest recycler of EPS in the United States, and one of the largest suppliers of loose-fill packaging, including filler beads, molding beads, and drainage beads. RAPAC was founded in 1984, and began supplying recycled loose-fill product in 1992. Today, notes Adams, “we believe we are the largest supplier of recycled-content loose-fill resin.”

|

RAPAC’s EcoSix resins are different than competing products because they contain at least 60% reclaimed foam from product that has been diverted from the nation’s landfills, explains Adams.

“We process about 1 million pounds of foam a month—averaging 10-14 million pounds annually,” says Adams. “Polystyrene gets a bit of a bad rap because it doesn’t go away, and it’s unsightly and messy in the environment, but it doesn’t do damage. The best alternative is if it can be collected and captured, and turned back into moldable EPS beads. Then PS is not really a problem.”

RAPAC collects primarily post-industrial EPS from companies that manufacture foam products such as foam packaging material (corner pads for electronics equipment, etc.), coolers. and other consumer products. That is because scrap foam is easier and more cost effective to collect, break down, and ship to RAPAC than packaging materials coming from individuals in a post-consumer situation.

RAPAC has collection sites with the proper equipment such as densifiers and hydraulic condensers that can take the scrap EPS material, and reduce the material from a normal weight of about a pound per cubic foot (which means shipping a lot of air, some 1500-2000 lb in a 53-ft trailer) to 30 lb per cubic foot. “That means we can ship 40,000-42,000 pounds in a 53-foot trailer,” says Adams. “When it comes in to our facility, we shred it, put it into an extruder, and turn it back into beads for new EPS products such as the WineLoc.”

ACH Foam’s Kansas City molding facility sends its scrap to RAPAC, and purchases the recycled EPS beads from RAPAC to use in its recycled content products. WineLoc with EcoSix required reinventing both the manufacturing and formulation processes.

Erich Brandt, VP of sales and marketing for ACH Foam Technologies, commented on the processing of EcoSix: “EcoSix recycled EPS molding beads have been available for several months through RAPAC, but the process of molding the recycled beads into packaging that is sufficiently strong took some months of trial and error. The first tests did not pass drop tests because the recycled molding beads would not bond together as well as virgin beads. As a result the packaging would break apart.

“Our technicians worked for months to perfect the molding process to bring our recycled EPS packaging up to ACH Foam’s quality standards,” said Brandt.

Adams agrees there are challenges to getting a 60% recycled-content material. “There are two key challenges to creating EPS packaging with higher quantities of recycled material,” Adams explains. “First is the problem of strength. As you add recycled molding beads to virgin beads, the product loses strength. Second, supply of the recycled beads is limited at this point in time. “

Because of that limited supply of EcoSix molding beads, ACH Foam is initially providing only WineLoc packaging products. However, EcoSix is available upon request in limited quantities in other EPS packaging that ACH produces. As ACH Foam further perfects the manufacturing process, the company anticipates offering additional packaging products that are made with the EcoSix material on a regular basis.

ACH Foam and RAPAC will continue their joint efforts at closed-loop recycling of EPS, and continuously increased recycled content in EPS packaging. “We aiming for as close to 100% recycled content as we can get,” said Brandt. “This is round one of an exciting development in environmentally friendly EPS packaging.” —Clare Goldsberry

About the Author(s)

You May Also Like