New Fire-Retardant Additive Formulated for Thermoplastics

GrafGuard 280-50N has the highest on-set temperature on the market, according to NeoGraf Solutions.

November 19, 2020

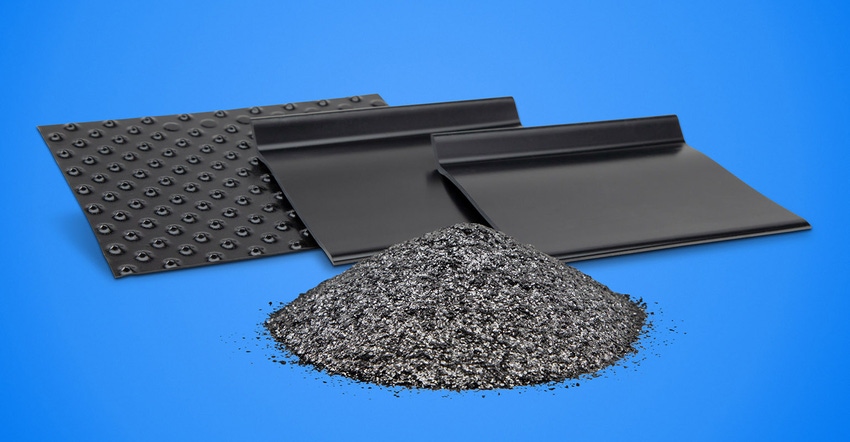

NeoGraf Solutions LLC announces the addition of GrafGuard 280-50N to its lineup of expandable graphite flake, non-halogenated, non-flammable, fire-retardant additives. The Lakewood, OH–based company specializes in the development and manufacture of natural and synthetic graphite sheets and powders used in consumer electronics, building and construction materials, transportation equipment, and sealing and gasketing.

Designed for plastics, roofing, and other construction and building materials, GrafGuard 280-50N specifically targets the thermoplastics industry. The additive performs optimally in specialty polymers with high processing temperatures, including composites and multi-functional systems with high melting points for both injection molded and thermoformed applications.

With a particle size of 50 mesh, or 300 microns, GrafGuard 280-50N has an on-set temperature of 280oC (536oF), the highest on-set temperature on the market, according to NeoGraf Solutions. The additive allows customers the freedom to process materials at higher temperatures to take advantage of the intumescence provided by the GrafGuard family of products, forming a large, thick char layer protecting the base polymer from the heat of the flames. There is no reaction below 280°C (536°F), with no volatile loss and no visible puffing.

“The new GrafGuard 280-50N offers customers a much wider range of polymer systems, such as polypropylene, polystyrene, PET, nylon, and ABS, than our previous products,” said Jeff Gough, Product Manager.

Existing GrafGuard customers who use a dryer to remove excess moisture or solvent from their systems often find the drying temperature is the maximum processing temperature, which limits the grades of GrafGuard graphite they can use. “If they need to dry the material at very high temperatures to drive off solvent or moisture, they can use a higher temperature if they switch over to the new GrafGuard 280-50N material,” explained Gough.

Depending on the polymer system, the processing temperatures have to be higher than the melt temperature of the polymer, so many thermoplastics are processed above 220°C (428°F), which can be problematic for the company’s previous-high temperature material, GrafGuard 250-50N. The new GrafGuard 280-50N is much more latent at these temperatures and above to about 280°C (536°F). This will allow customers to use typical processing parameters and simply add GrafGuard 280-50N as an active fire retardant.

Thermoplastics is a new market for this material, since graphite additives traditionally do not work because of the high processing temperatures. “There are some chemicals that can compete with the materials, but most of the traditional fire-retardant chemicals react around 250°C (482°F), so they would be difficult to incorporate into high-temperature applications,” Gough said. “The primary exception would be magnesium hydroxide, which we recommend as a synergistic material to be used with GrafGuard 280-50N.”

About the Author(s)

You May Also Like