Advanced Recycling LCA Analysis Highlights Sustainability

Compared with landfilling or combustion, advanced recycling offers a more climate-friendly transformation for hard-to-recycle plastics.

A recent analysis of life cycle assessments (LCAs) for advanced recycling technologies concludes that this form of recycling significantly reduces greenhouse gas (GHG) emissions and fossil energy vs. traditional end-of-life scenarios for plastics.

Researchers at the City College of New York (CCNY) Grove School of Engineering performed the analysis and published their results in a report commissioned by the American Chemistry Council.

The researchers studied 13 advanced recycling LCAs conducted since 2020. All the advanced recycling technologies were available at large scale for commercial applications. They included:

Thermal conversion processes, such as pyrolysis, reforming, and gasification.

Chemical depolymerization methods, such as glycolysis, hydrolysis, and methanolysis.

“As advanced recycling becomes increasingly efficient, it is poised to play a major role in achieving global sustainability goals,” says report co-author Marco J. Castaldi, professor of chemical engineering and director of CCNY’s Earth Engineering Center.

All the examined LCAs showed that advanced recycling of plastics performs better on GHG emissions than conventional approaches.

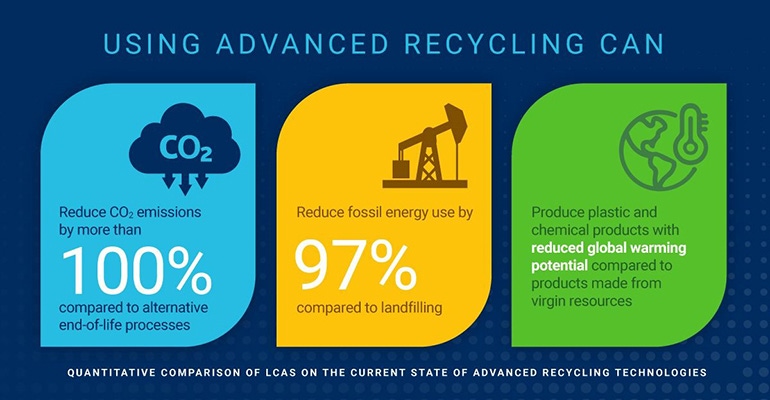

The report states, “Using advanced recycling technologies compared to alternative end-of-life processes, including production with fossil naphtha, incineration, and landfilling, can reduce carbon dioxide equivalents (CO2eq) emissions by over 100%.”

A value greater than 100%, which can be achieved with credits earned from avoided products and/or energy, indicates prevented emissions.

Advanced recycling can also shrink use of fossil-based energy — by up to 97%, compared with landfilling — the researchers found.

In addition, all the LCAs showed that advanced recycling contributes to a circular economy for plastics.

The post-use plastic inputs for the various advanced recycling (aka chemical or molecular recycling) processes differ somewhat, as do the outputs.

Typical inputs for thermal conversion are mixed plastics comprising some combination of polyethylene (PE), polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), and/or polyvinyl chloride (PVC). Common inputs for chemical depolymerization are PET and colored polyesters.

As for the outputs, thermal conversion results in pyrolysis oil and synthesis gas, which can be used to produce chemicals, fuels, and hydrocarbon feedstocks. Chemical depolymerization creates monomers and molecules useful in producing new plastics, including PET and PS.

Advanced recycling “can transform hard-to-recycle plastics into a multitude of high-value feedstocks, reducing the need for fossil resources and limiting the environmental impact of waste management,” Castaldi says. “Equally important, the data suggest that our transition to a more circular economy will dramatically improve climate outcomes.”

About the Author(s)

You May Also Like