Sabic Study Underscores Integration, Styling, and Aerodynamics Benefits of PC-based Rear Quarter Windows

All of the designs accommodate well-established processing methods and secondary operations.

December 6, 2021

Sabic has announced the results of a recent design study on automotive rear quarter windows that explored the advantages of polycarbonate (PC) resins for creating differentiated styling, consolidating components, integrating functions, and enhancing aerodynamics. These concepts reveal multiple new opportunities to significantly expand design freedom, control costs, and reduce weight by replacing traditional glass with transparent, impact-resistant Lexan resins.

The study, conducted by Sabic designers and engineers, builds on the company’s decades-long history in automotive glazing technology using its Lexan PC resin. In addition to rear quarter windows, the Sabic team produced stylish design concepts for rear side windows. The data is available to support the feasibility of these designs, all of which can use well-established processing methods and secondary operations.

“As industry trends such as vehicle electrification continue to evolve, Sabic is seeing major new opportunities for our materials to radically change automotive styling, while simultaneously addressing the longstanding challenges of weight-out, cost-out, and sustainability,” said Abdullah Al-Otaibi, General Manager, ETP & Market Solutions, Sabic. “The latest concepts from our study aim to inspire exciting new window designs that address these needs by combining beautiful aesthetics with practical performance and established processing methods. Sabic’s Lexan resins have a proven track record in automotive glazing applications, and we continue to work with our customers to proactively deliver cutting-edge ideas and innovations that can benefit OEMs, tier suppliers, and consumers alike.”

Wraparounds, panel swaps, integrated lighting, and more

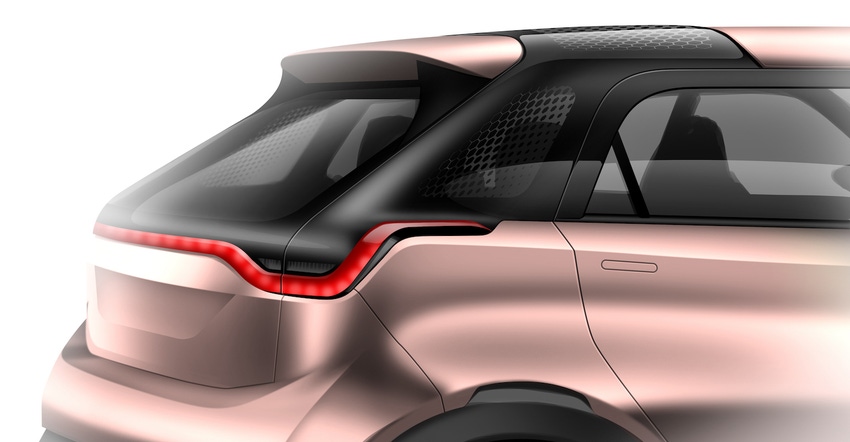

Many of the new Sabic concepts feature the use of Lexan resin in curved wraparounds that seamlessly flow into other portions of the vehicle while integrating rear lighting, door latches, D-pillar trim, and even sunroofs. Integrations and complex curvatures like these typically cannot be achieved with glass. Part and function integrations can enhance aerodynamics to improve fuel economy and electric vehicle (EV) battery efficiency and range. They also create a highly streamlined look for the vehicle.

One rear quarter window concept integrates an airflow separator for increased aerodynamic efficiency and incorporates styling strokes to add visual appeal. Another concept integrates a backlit EV charge level indicator within the window. Alternatively, the rear quarter window could integrate a different or more distinctive type of indicator or an animated light display.

In another case, Sabic created a rear quarter window with an expressive 3D curvature that smoothly wraps around the D-pillar, into the sunroof, and down the back side. This concept combines the window with the taillights. A variation on this rear quarter window design features a raised panel covering the D-pillar area. This window enhancement can be created in the same color as the body to establish a floating-pillar effect and can even be swapped by the consumer for a different panel if a special color or effect is desired.

The new Sabic study also includes innovative design concepts for the rear side window. For example, one unique design features a window and door latch that are mated to a trim insert in the D-pillar. The result is a sleek, aerodynamic design.

Clear advantages over glass

Although glass has dominated the automotive glazing sector for years, mainly because of the low cost for simple curved components, disruptors such as EVs are prompting the industry to re-imagine vehicle design. In the process, traditional materials like glass have come under scrutiny and are increasingly being replaced by safer, lighter, higher performing engineered plastics. Sabic’s PC glazing offers exceptional advantages over glass, beginning with significantly lighter weight.

With PC, designers gain the freedom to create curved forms, sharp angles, and other configurations that cannot be achieved with glass. Proven technologies such as 2K (two-shot) and 3K (three-shot) injection molding can be used to produce these shapes. Sabic has invested in the development of a 3K injection molded sunroof to build competencies in molding large transparent and semi-transparent parts.

PC is also easier to recycle than glass, which faces roadblocks due to its high transportation costs, potential for contaminating single-stream recycled content with broken fragments, and shrinking end markets for the material, particularly automotive. Sabic is interested in pursuing supply chain collaboration with industry partners to explore the chemical upcycling of PC materials used in rear quarter windows and rear side windows.

You May Also Like