X2F, Covestro Collaborate on In-Mold Electronics for Automotive Lighting

Thermally conductive polycarbonate heat sinks are up to 49% lighter than conventional cast-aluminum counterparts.

September 27, 2022

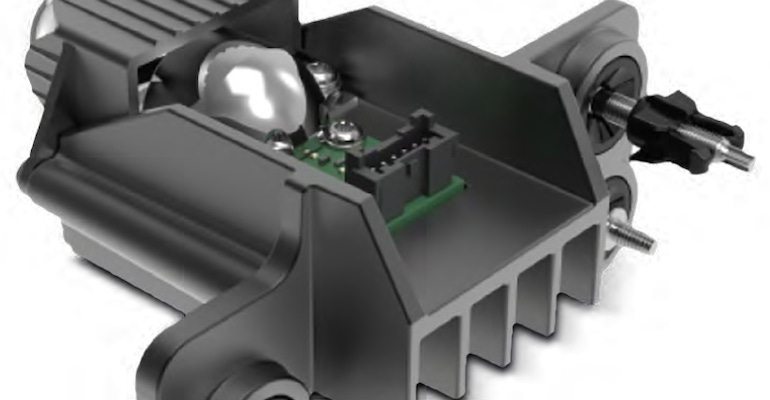

Injection molding innovator X2F and materials supplier Covestro have combined forces to develop a thermally conductive automotive heat-sink with in-mold electronics using X2F’s controlled-viscosity molding technology. Application samples will be displayed at Covestro’s booth (hall 6, booth A75-1/A75-2) during K 2022 on Oct. 19 to 26 in Düsseldorf, Germany.

This new product is designed as an alternative to cast aluminum heat sinks for automotive OEMs and processors. It is up to 49% lighter and more cost effective, according to the companies.

X2F technology is production ready

Molded from Makrolon polycarbonate (PC), the heat sink is part of an in-mold assembly that can be used to integrate LED modules directly into the headlamp housing, eliminating the weight and labor associated with the installation of brackets, screws, thermal pastes, and adhesives. X2F technology is production ready and has been demonstrated in high-volume series manufacturing for other applications. For its part, Covestro continues to pioneer the use of in-mold electronics (IME) coupled with the heat management that Makrolon PC provides.

Enhanced thermal-management performance

“This new program involves using controlled-viscosity molding by X2F to attach the LED module directly onto the thermally conductive heat sink without fundamentally changing the heat-sink adjuster module design,” said Paul Platte, Senior Marketing Manager, Covestro. “We are pleased with the outcome so far of the X2F project, where we have recently seen enhanced thermal-management performance compared to traditional injection-molded processes and look forward to how the automotive industry will adopt the technology.”

X2F’s process enables sensitive electronics to be insert molded, thus providing functional integration, heat management, modularity, and miniaturization. “This innovative technology enables the manufacture of previously impossible-to-mold thermoplastic parts that provide step-change improvements for our customers,” explained Reza Garaee, X2F Senior Project Manager. “In the case of heat sinks, it dramatically streamlines production, reduces manufacturing times, eliminates fasteners and pastes, and increases product design flexibility. This can be a game-changer for OEMs, and we’re thrilled to launch this new collaboration with Covestro,” said Garaee.

X2F technology suitable for molding critical medical components

X2F’s ability to mold thermally conductive materials has applications far beyond heat sinks. Thermal management is critical for superior performance in batteries, motors, and printed circuit boards. The X2F controlled-viscosity, low-pressure technology allows molding of highly filled materials, which is not possible with other manufacturing approaches. The result is 30 to 200% improvement in performance, depending on the application and materials used.

X2F recently added a rotary table, which reduces cycle times and opens up higher-volume production for its controlled-viscosity molding machine. The rotary table enables X2F to reach production volumes of up to four million parts per year with one unit, depending on the cycle time, for the manufacture of critical components in the electronics, automotive, industrial, and medical industries.

You May Also Like