Carbon-Fiber Composite Achieves Metal-like Thermal Conductivity

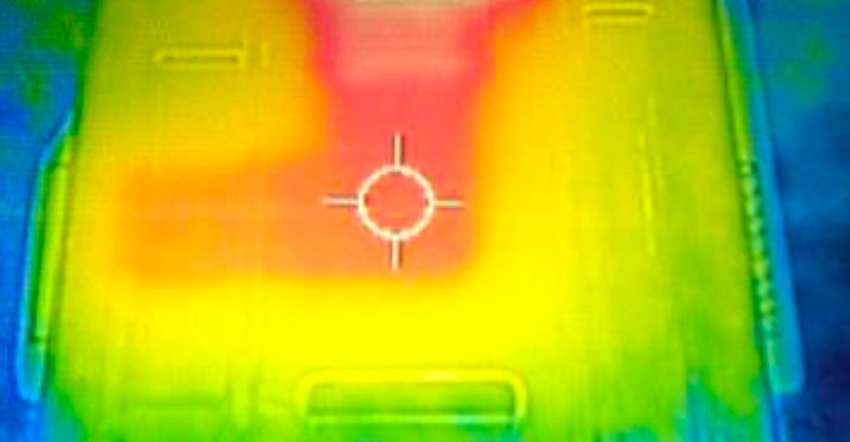

Heat is dissipated through thermal conduction paths inside the material, helping to suppress battery degradation in mobility applications while boosting performance in electronic devices.

May 25, 2021

Japan’s Toray Industries Inc. has developed a thermal conductivity technology that raises the heat-dissipating properties of carbon-fiber-reinforced plastic (CFRP) to that of metals. Applying this technology to CFRP dissipates heat effectively from its sources through thermal conduction paths inside the material. This helps suppress battery degradation in mobility applications while boosting performance in electronic devices.

Common applications for this light, strong, and rigid plastic include aircraft, automobiles, infrastructure components, sporting goods, and electronic devices. Boosting the heat dissipation of CFRP when it is used as a structural material in advanced mobility is important in preventing batteries from deteriorating because of heat buildup during charging. However, CFRP is less thermally conductive than aluminum alloys and other metals, prompting efforts to enhance heat dissipation by employing external or internal graphite sheets. These sheets are easy to fracture, scatter, and damage, however, and compromise the performance of CFRP.

Over the years, Toray has used proprietary technology to develop and apply rigid, porous CFRP forming three-dimensional networks with short carbon fibers. On this occasion, Toray created a heat-conductive layer employing a porous CFRP support that safeguards the graphite sheets. Laminating CFRP prepreg on this thermally conductive layer enables Toray to attain a thermal conductivity above that of metals. That would be impossible with regular CFRP without compromising the mechanical properties and quality of the material.

Prepreg is a sheet-like intermediate material made by impregnating fibers with resin to reinforce them. Common applications are aircraft fuselages, main and tail wings, and other primary structural components. It is also used in golf club shafts, fishing rods, tennis racket frames, and other sports equipment.

Toray can modify the thickness and lamination positions of the graphite sheets that form the thermal conduction paths, thus enabling a flexible thermal-management design that controls the paths to release or use heat for CFRP cooling efficiency and heat diffusion.

Toray’s breakthrough is a technological solution for efficiently dissipating heat from batteries and electronic circuits without undermining the lightness of CFRP. The company anticipates that CFRP applications employing its technology will include advanced mobility, mobile electronic devices, and wearables demanding lightness and heat dissipation.

About the Author(s)

You May Also Like