Chopped fiberglass PP compounds offer industry leading modulus, impact

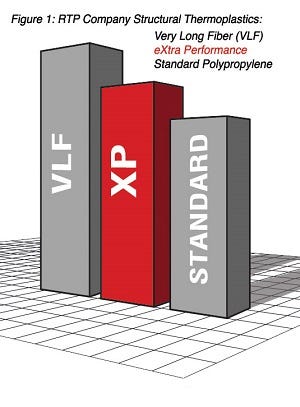

Compounder RTP Company (Winona, MN) has developed a series of thermoplastic compounds formulated for higher strength, modulus and impact properties than any standard chopped fiberglass polypropylene (PP) compounds available on the market today.

September 16, 2015

|

Chopped fiber PP compounds boast performance close to long fiber alternatives. |

With strength, stiffness, and impact resistance performance that is close to RTP's Very Long Fiber (VLF) compounds, combined with the lighter weight and chemical resistance of standard PP compounds, RTP 100 eXtra Performance (XP) compounds are said to provide a new realm of design possibilities for applications in the automotive, furniture, appliance, storage, industrial/construction, electronics, and energy markets.

In comparison to common glass fiber reinforced PP at similar load levels, RTP 100 XP Compounds exhibit up to 20% higher modulus values and twice the impact resistance. Further, their lighter density makes RTP 100 XP compounds an ideal choice for lightweighting via metal replacement. Due to their inherent chemical resistant properties and non-hygroscopic nature, RTP 100 XP compounds are also reportedly an excellent alternative to nylon or other compounds where moisture can reduce load bearing capabilities.

RTP 100 XP compounds are available from RTP Company worldwide as standard pellets in formulations containing from 10-50 weight per-cent glass fiber reinforcement, and can be easily injection molded into large or small complex geometries. Additional additive technologies may be incorporated to create robust compounds, engineered to meet demanding requirements such as long term heat aging, cold weather impact resistance, flame retardance, , ultra violet protection, or compliance with government agency approvals.

About the Author(s)

You May Also Like