German Project Aims to Simulate Thermal Runaway in EV Batteries

The project will facilitate increased take-up of plastics in battery enclosures.

February 13, 2024

At a Glance

- The SiKuBa project targets “safe and sustainable plastic-based battery housings”

- Simulation will boost cost- and time-efficiency in the development phase

- Plastic battery enclosure pioneer Kautex Textron is part of the project consortium

Plastic enclosures have many advantages over metal enclosures: They are lighter, more sustainable, cheaper to produce, and have better electrical insulation. In the event of a damaged cell, the battery housing can be exposed to enormous thermal loads if thermal runaway of individual cells occurs. In the worst case, this reaction can spread to adjoining cells, known as thermal propagation. The battery housing has a high safety-relevant function in this case, as it can contain spread of the resulting hot gases and particles. One challenge, however, is proving its safety, which is complex and expensive.

German ministry invests $2.8 million in project

To this end, Germany’s Federal Ministry for Economic Affairs and Climate Action has invested €2.6 million ($2.8 million) in funding for Project SiKuBa. This research initiative will study formation and propagation of hot gas and particle flows and their interaction with structural elements experimentally as well as via simulation models, which will lead to increased cost- and time-efficiency in the development phase. It will also be possible to assess battery safety regarding load case scenarios, materials, and component design. SiKuBa is an acronym for “safe and sustainable plastic-based battery housings.”

Research for safe integration

Farasis Energy is part of the research consortium, along with Kautex Textron and the Fraunhofer Institute for High-Speed Dynamics, Ernst-Mach-Institut (EMI). Their efforts are aimed at making plastic-based battery housings safer by means of virtual design and, thus, increasing the safety of electric vehicles (EVs).

Farasis Energy, a developer and producer of high-performance lithium-ion battery technology and pouch cells for electromobility, is leading the method development of the simulation model for mapping thermal runaway of individual cells and propagation in the module. The company is also providing support on all battery-related topics within the project. The three-year project started in July 2023.

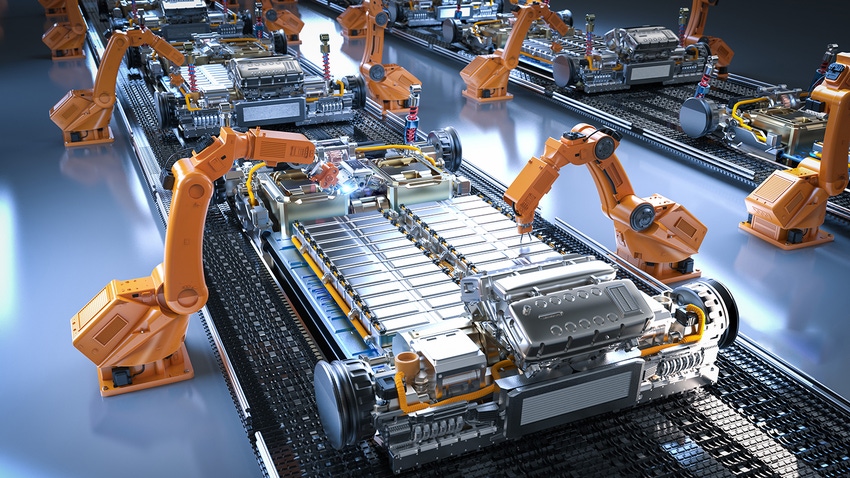

The SiKuBa project aims to develop simulation methodologies for “safe and sustainable plastic-based battery housings.” Image courtesy of Kautex Textron.

Fundamental effects are being investigated at the laboratory level, including thermomechanical material behavior and cell degassing. The knowledge gained is being integrated into simulation models and validated by physical tests on a demonstrator housing that closely resembles the planned product. The simulation methods developed not only enable significant time and cost savings during the development phase, but also support comprehensive assessment of battery safety under a variety of load case scenarios, materials, and component design.

Benefits for future product development

Farasis Energy, together with its partners, will develop a detailed model for simulating thermal runaway or enhance existing models within the company. In future development processes for module and pack projects, the insights gained from the developed simulation model will be utilized to expedite development and save on costly testing. Additionally, these simulation models enable the company to achieve a quicker and safer integration of plastic-based module and pack enclosures.

About the Author(s)

You May Also Like