High-gloss Polyamide Proffers Premium Surface Finish

BASF’s new Ultramid grade targets application in high-quality surfaces in the car interior

December 18, 2020

Numerous trends are influencing the automotive industry: automated driving, electromobility, sustainability, lightweight construction, energy efficiency. In addition, the interior is getting into the focus by designers and developers. The transformation into a feel-good space on four wheels is increasing very fast. The haptics and visual appearance of components are becoming even more important. BASF is presenting innovative materials for premium and appealing surfaces to give the interior a distinctive look.

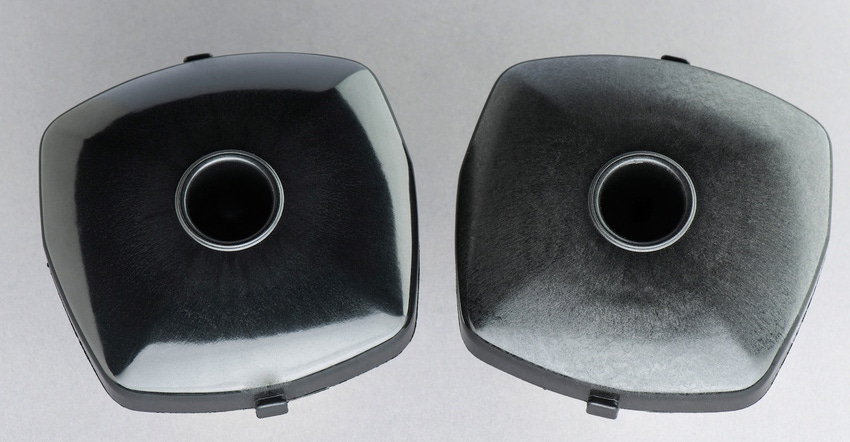

After the successful market launch in 2017 of Ultramid Deep Gloss, a special polyamide for durable high-gloss trim parts, a new generation of surface-improved structural materials is now following with Ultramid B3E2G6 SI BK23353 and Ultramid B3E2G10 SI BK23353. The glass fiber reinforced types based on polyamide 6 impress with very low emission values and good UV stability and are therefore ideally suited for the use in functional visible parts in the interior.

“With the newly developed SI grades for functional parts in the car interior with premium surface quality, we are offering a new solution to the existing portfolio," explains Rainer Xalter, product developer in the Performance Materials division at BASF. “Structural components with plain, matt and textured surfaces can be produced in just one process step. An additional painting of the component to upgrade the surface is not necessary." Visible fiber turbulences, which are commonly observed on surfaces of standard types, are largely suppressed by the new SI grades. Due to the variable glass fiber reinforcement, parts with medium to very high stiffness can be manufactured.

Ultramid B3E2G6 SI BK23353 and Ultramid B3E2G10 SI BK23353 are therefore suitable for air ventilation lamellas, steering column levers, armrests, cup holders or even door handles. The good intrinsic material properties of Ultramid enable high long-term use characteristics. In addition, the new materials are insensitive to commercially available cleaning agents. An important property with regard to the increasing popularity of "shared mobility", which requires frequent professional cleaning of the interior.

“Thanks to our expertise in research and development, we can cover the increasing demand for versatile materials for the interior and support the trends towards more design and atmosphere in the car. Since the demands of designers and automobile manufacturers are constantly growing, we try to provide the right solution for every application with our products,” adds Ragnar Stoll, Interior Marketing Manager in the Performance Materials division at BASF.

About the Author(s)

You May Also Like