JEC Composites Innovation Awards: Finalists in Aerospace Process Category

Entries from Spirit AeroSystems, German Aerospace Center, and Airbus DS make up the final three in this category.

January 25, 2024

At a Glance

- Fastener-free aircraft cabin made entirely of thermoplastic composite

- Additive functionalization of multi-curved thermoset shell

- External wing skin cover fabricated from PEEK composite

The 2024 edition of the JEC Composites Innovation Awards has kicked off with the naming of three finalists per category. The awards ceremony will take place in Paris on Feb. 8, 2024. Here we profile the successful entries in the Aerospace Process category.

Aspera welded thermoplastic composite demonstrator

Company: Spirit AeroSystems (USA)

Partners: A&P Technology (USA), Concordia Fibers (USA), Electroimpact (USA), Mitsubishi Chemical Advanced Materials (USA), NIAR (USA), Victrex (USA)

![ASPERA1_650x428[49].png ASPERA1_650x428[49].png](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/blt74688e01d7eea91c/65b2e517afc23e040ae81fdc/ASPERA1_650x428[49].png?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of Spirit AeroSystems

Description: In preparation for future aerospace challenges, Spirit AeroSystems has fabricated details utilizing automated fiber placement, stamp forming, and novel pressure intensification processes. Welding is done with the patented Co-Fusion and induction processes, demonstrating fastener-free high-rate manufacturing. Aspera is representative of a large portion of a typical commercial aircraft cabin but is made entirely from thermoplastic composite details welded together.

Fastener-free assembly methods are adopted to minimize weight and cost while utilizing rapid fabrication processes that enable future high-rate single-aisle commercial aircraft production. Both patented and proprietary novel fabrication and welding processes are used to make the part. These processes were developed internally by Spirit AeroSystems and represent state-of-the-art thermoplastic composite technologies and tooling methodologies.

Key benefits

Rapid fabrication process cycle time, with a dramatic reduction in energy consumption

Elimination of fasteners and associated scrap, rework, and weight

Materials used can be reworked in process and recycled at end of life

Efficient combination of welding and consolidation cycles with patented process

Development of rapid in-situ induction welding process with minimal unused heat energy

EmpowerAX – additive functionalization

Company: German Aerospace Center

Partners: 9T Labs AG (Switzerland), Airtech Europe (Luxembourg), Ansys Switzerland GmbH (Switzerland), CEAD B.V. (Netherlands), Ensinger GmbH (Germany), Fiberthree GmbH (Germany), Fill GmbH. (Austria), Hans Weber Maschinenfabrik GmbH/Weber Additive (Germany), Prime Aerostructures GmbH (Austria), Siemens AG (Germany), Suprem SA (Switzerland), SWMS Systemtechnik (Germany)

![EmpowerAXDemo650x461[58].jpeg EmpowerAXDemo650x461[58].jpeg](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/blt7fb7a45d0bf459c9/65b2e623ebbcff040aa34fcb/EmpowerAXDemo650x461[58].jpeg?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of German Aerospace Center

Description: The EmpowerAX demo part is a multi-curved thermoset shell additively functionalized with short and continuous fiber-reinforced elements realized by the DLR Innovation Lab and 12 EmpowerAX members. It demonstrates the industrially available process chain for additive functionalization. Cost-efficient composite manufacturing is combined with the agility and design freedom of additive manufacturing.

Key benefits

Cost-efficient composite manufacturing

Overprinting of a multi-curved shell

Combines thermoset and thermoplastic polymers

Short and continuous fiber-reinforced materials

Industrially available process chain

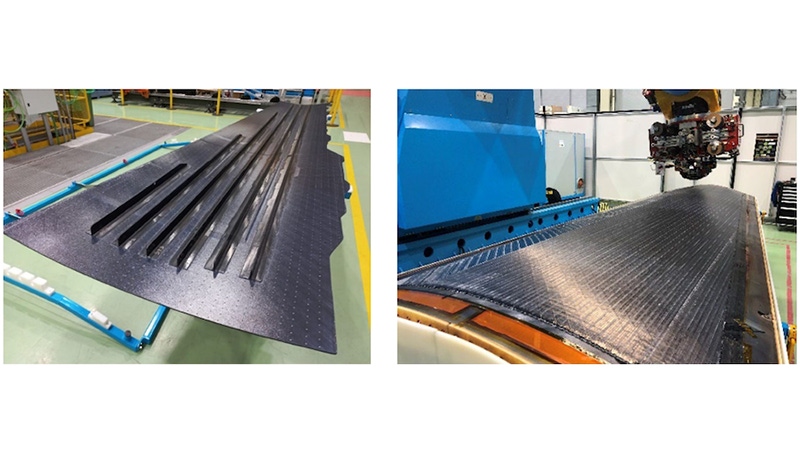

One-shot in situ consolidation wing upper cover

Company: Airbus DS – Defence & Space (Spain)

Partner: FIDAMC (Spain)

![Airbus_DS2_650x228[26].png Airbus_DS2_650x228[26].png](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/blt358d179942d5f160/65b2e68331e2ca040a3438bd/Airbus_DS2_650x228[26].png?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of Airbus DS

Description: One-step in situ consolidation of polyetheretherketone (PEEK) thermoplastic resin based carbon-fiber composite was used to fabricate a transport aircraft external wing skin cover, which is part of the primary structure, through an ecofriendly process. This approach enables low energy consumption processing and end-of-life recycling.

Thermoplastic resin based composites are a key enabler toward sustainability of composite structures in aerospace due to their recyclability and performance. Airbus Defence and Space (engineering) and FIDAMC (manufacturing) have produced a thermoplastic in-situ consolidated (ISC) upper cover for airframe under the ITD CleanSky2 platform for integration into an outer external wing box specimen. This is the first demonstrator of a primary structure using ISC with integrated stringers and without a post-consolidation step. An exhaustive testing campaign substantiated technology readiness level (TRL) 5, including mechanical characterization, detail, subcomponent level, and full scale up to ultimate load.

Key benefits

Weight performance through structural integration in one-shot consolidation

Improved recyclability

Automation

Eco-efficient processing

Promising new repair technology via welding

About the Author(s)

You May Also Like