Kureha to Boost PVDF Production

The fluoropolymer resin is a key component of EV lithium-ion batteries.

August 30, 2023

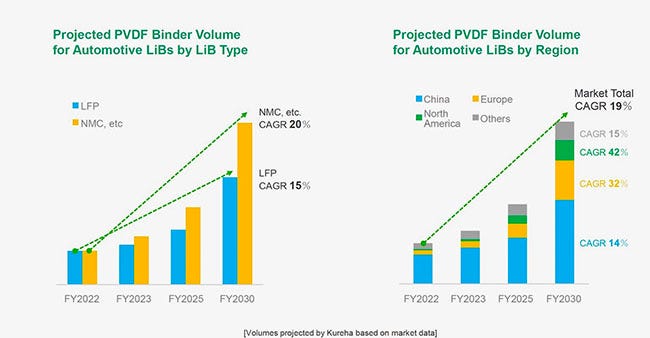

Japan’s Kureha Corp. plans to increase production capacity for polyvinylidene fluoride (PVDF) at its Iwaki factory in Fukushima, Japan. PVDF is used as a binder material for lithium-ion batteries (LiBs) and as an engineering plastic in various industrial applications such as chemical process and semiconductor manufacturing equipment.

Kureha intends to boost capacity from the current 11,000 to 20,000 tonnes/year by March 2027 through debottlenecking and the addition of a new 8,000 tonnes/year production line. Further, capacity is expected to rise as much as 40,000 tonnes/year by March 2031. The Kureha Group currently manufactures PVDF at the Iwaki factory (6,000 tonnes/year) and its wholly-owned subsidiary in China (5,000 tonnes/year).

|

Lithium ferrophosphate (LFP) and nickel manganese cobalt (NMC) are types of lithium-ion battery chemistries. |

Electric vehicle (EV) sales have been rising rapidly in recent years, particularly in Europe and China, and demand for LiBs has been rising in parallel. Market watcher BloombergNEF forecasts EV sales to grow to 26.6 million units in 2026, accounting for 30% of overall passenger vehicle sales.

About the Author(s)

You May Also Like