Microwave Heating Slashes Energy Use in Carbon-Fiber Production

The new process is 50% more energy-efficient than the conventional method, which employs oxidation ovens and carbonization furnaces.

May 12, 2022

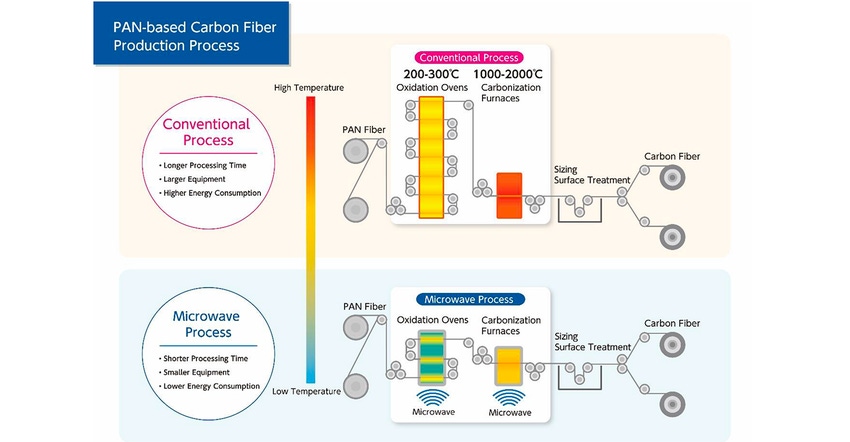

Japanese firms Mitsui Chemicals and Microwave have developed what they call “an innovative, eco-friendly carbon-fiber (CF) manufacturing technology using microwaves.” The new process employs microwaves to heat the polyacrylonitrile (PAN) fiber precursors, both during the oxidation process — the most energy-intensive part of CF production — and during subsequent carbonization.

As well as employing more compact equipment, the new technology cuts energy consumption by approximately 50% and offers a substantial reduction in processing time compared with the conventional method, which utilizes oxidation ovens heated from 200° to 300°C and carbonization furnaces maintained at temperatures of 1000° to 2000°C.

Microwave heating is efficient in that it is direct and selectively focuses on the PAN fibers alone. Conventional heating, on the other hand, is indirect and heats the entire oven or furnace.

Going forward, the two companies intend to construct a pilot facility to validate the process. Eventually, energy-efficient carbon fiber will be targeted at the mobility sector.

About the Author(s)

You May Also Like