New Heat-Shield Technology Outperforms Conventional Products in Lighter Package

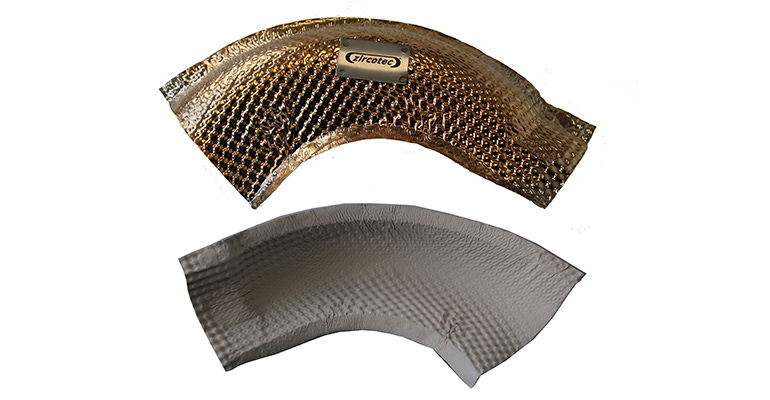

ZircoFlex Shield reportedly achieves better thermal performance at 40% lower weight and 46% lower volume than competing heat-shield products.

March 9, 2021

New heat-shield technology is said to outperform competing products while achieving a significant reduction in weight and packaging space. Compared with conventional technologies, ZircoFlex Shield delivers a 35% overall improvement in performance, according to automotive and motorsports heat-management specialist Zircotec.

The patented technology comprises a traditional insulation core combined with Zircotec’s proprietary thermal barrier coatings. Zircotec describes the advantages, as follows:

At half the thickness of the next-best heat shield from another manufacturer, ZircoFlex Shield achieved a 40% improvement in heat shielding with as much as a 125o C reduction in surface temperature in exhausts.

It secures the same performance as the next-best competitor in almost half the volume.

Shield weight is reduced by up to 40%.

Many years of research and testing have led to the development of ZircoFlex Shield, said the company. Extensive real-world testing has been carried out on the engine of a four-cylinder British touring car fitted with different exhaust pipes using industry-leading insulation materials at various thicknesses.

The research and development program examined both detachable and integral heat shields at different engine speeds and loads, and simulated typical under-hood temperature conditions. The key area of interest was at high rpm and full load, where heat flux is highest. Exhaust gas temperatures from 660 to 730o C (1,200 to 1,346o F) were measured entering and exiting the exhaust pipe, along with surface temperatures from 116 to 695o C (240 to 1,283 o F).

Measurements have shown conclusively that ZircoFlex Shield has significantly better thermal performance at a lower weight (by 40%) and lower volume (by 46%), according to the company. This will enable engines to run more efficiently and cars to travel significantly faster.

“If you can retain more heat within the exhaust gases of a turbocharged engine; if you can shield the driver from heat while the engine idles in traffic jams; and if you can lower the temperature under the bonnet at a given engine speed — well, then, you are seriously increasing race performance and efficiency of on-road cars and off-highway commercial vehicles, such as in AgriTech,” said Graeme Barette of Zircotec. “That’s what ZircoFlex Shield delivers.”

Thermal protection is particularly important in electric vehicles, added Barette, since batteries are very dependent on their environment. “It is well documented that high and low temperatures can reduce the battery life expectancy and journey distance before re-charging is needed. This extended life and keeping more of the heat within the car have obvious environmental benefits, as well as driver comfort.”

Zircotec has expertise in plasma-spray processing and thermal barrier solutions and develops and produces high-performance surface coatings and finishes. It works with most Formula 1 teams and leading OEMs.

The company is expanding its reach into other sectors, including electric vehicles, oil and gas, marine, power generation, and aerospace. These industries have stringent emissions targets and heat-management requirements, and Zircotec’s technology can provide a solution to manage heat without adding excessive weight, said the announcement that went out today.

Along with heat-shield solutions, Zircotec offers a range of industry coatings including plasma-applied ceramic coatings, carbon composite coatings, anti-wear coatings, and ceramic fabrications. It has also developed a conductive ceramic battery coating that provides RFI shielding with a weight saving of up to 4 kg per m2 compared to aluminum. This enables manufacturers to use carbon or plastic composite battery casings for hybrid and electric vehicles rather than much-heavier aluminum.

About the Author(s)

You May Also Like