NYCOA to Launch Plasticizer-free Long-chain Polyamide Portfolio

NXTamid L is equivalent in performance to PA 12, but offers sustainability advantages.

April 15, 2024

Nylon Corporation of America Inc. (NYCOA), a custom manufacturer of engineered polyamide resins, is poised to launch NXTamid L, a proprietary long-chain polyamide (PA) as a replacement for PA 11 and PA 12 in various applications. The company will introduce the material in booth S34115 at NPE2024, which runs from May 6 to 10 at the Orange County Convention Center in Orlando, FL. The latest launch accelerates the supplier’s transformation into a specialty polyamide (PA) supplier.

NYCOA has collaborated with some of the largest end users of long-chain polyamide resins to develop an alternate solution that offers several advantages over the traditionally imported resins. Over the decades, OEMs and processors have been forced to rely on imports from Europe and Asia, which not only carry costly tariffs but have also been affected by shortages and supply-chain disruptions.

Outperforming PA 12 and PA 11.

Depending on the application, NXTamid L delivers performance that is equivalent or better than traditional PA 12 and PA 11 resins, while offering a broad range of customization options. The material has a higher service temperature than PA 12 and offers a great degree of flexibility and chemical resistance. It is also more sustainable, with some grades having bio content exceeding 50% of the material composition.

“Our customers approached us looking for alternate solutions every time there was a shortage or supply disruption of long-chain polyamides in the North American market,” said Bill Baker, vice president of sales for NYCOA. “We’ve responded to our customers’ needs and that of the market with an innovative solution that is not only a performance equivalent but also versatile and sustainable. Domestic OEMs and processors can now be assured of stable supply to meet their production needs for various transportation, sporting goods, and industrial applications.”

Plasticizer-free option.

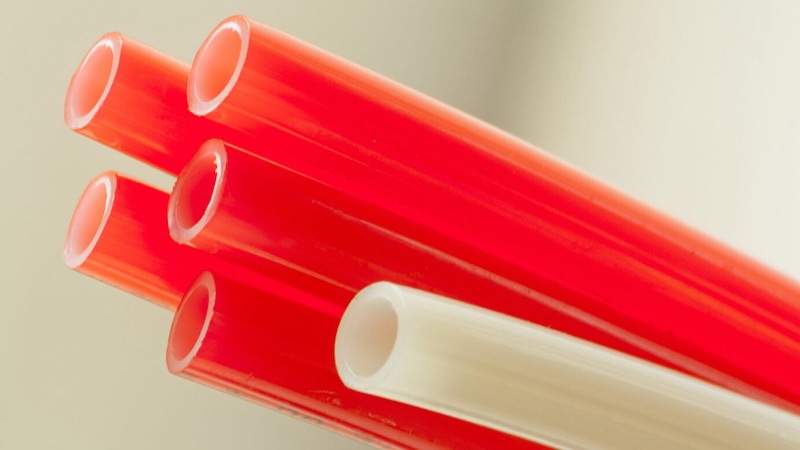

The biggest advantage of NXTamid L is that customers have an option to go completely plasticizer-free without compromising on mechanical properties.

Plasticizers such as BBSA (n-butyl benzene sulfonamide) are widely used by resin manufacturers and compounders to soften base polyamide resins. The plasticizers have a lower molecular weight and tend to migrate out during compounding/processing and during their service life, especially at higher temperatures. This migration causes a change in the material’s mechanical behavior, making it stiffer and also causing premature wear of seals and gaskets in the tubing industry.

Additionally, the plasticizer itself has raised environmental and health concerns. NXTamid L offers a plasticizer-free solution resulting in better long-term stability compared with other plasticized long-chain polyamides. NYCOA has received strong traction from multiple customers looking for next-generation plasticizer-free alternates, according to Baker. Plasticizer-free NXTamid L grades are already being supplied to multiple customers in commercial quantities.

Higher melt temperature, lower moisture absorption.

Some of the other benefits of NXTamid L are higher melting temperatures, lower moisture absorption, and better dimensional stability than PA 12 and PA 11. The material’s dimensional stability is another important characteristic that differentiates it from short-chain nylons such as PA 6 and PA 66. It has excellent chemical resistance to various alcohols, industrial chemicals, and zinc chloride, making it ideal for the transportation and tubing markets.

NYCOA’s NXTamid L portfolio consists of grades designed and optimized for various applications and processing technologies such as injection molding, extrusion, rotomolding, and blow molding.

NYCOA also notes significant environmental benefits of sourcing material locally in North America. Studies have indicated that resin produced domestically can help save a significant amount of shipping-related carbon emissions over materials produced and shipped by sea from Europe and Asia.

About the Author(s)

You May Also Like