Research Consortium Targets Climate-Friendly Headlamp Concept

The Nalyses research project looks at the product’s entire life cycle, aiming to apply polycarbonate in sustainable automotive illumination.

March 20, 2023

How can complex products such as car headlights transition to a circular economy? This question is being addressed by a consortium led by Forvia group company Hella, which also includes polycarbonate (PC) supplier Covestro, BMW, compounder geba Kunststoffcompounds as well as the Fraunhofer Institute for Mechatronic Systems Design IEM, the Heinz Nixdorf Institute, and Hamm-Lippstadt University of Applied Sciences. The aim is to optimize sustainability throughout the entire life cycle in order to make products more climate-friendly and conserve resources.

The Nalyses research project kicked off in October 2022 and is designed to last three years. It is funded by the German Federal Ministry of Education and Research (BMBF). Miele is also involved in the project as an associate partner in order to evaluate the transferability of the results to the production of home appliances.

Advanced materials such as PC fulfill important requirements in the development and design of today's headlights, including the transparent cover of such lighting systems. They also play an important role when it comes to their reuse, remanufacturing, or end-of-life material recycling. Current developments are also aimed at a more sustainable raw material base.

"The focus of our involvement in this pioneering project is the design of a materials and recycling strategy. We have extensive expertise in this area," explained Jan Helmig, global technical marketing manager for lighting and project manager for Nalyses at Covestro. "As part of the new project, we want to work with partners to develop a near-series solution that incorporates the entire product cycle."

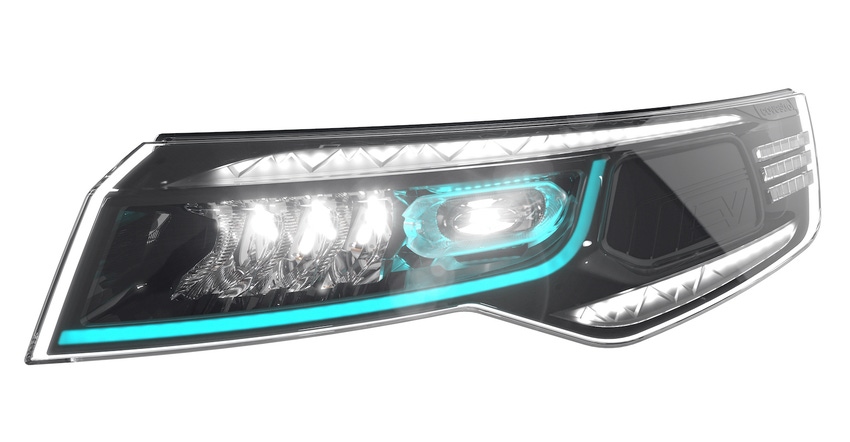

Several years ago, Covestro presented a visionary headlamp concept for vehicle lighting of the future. The modular approach is based on different types of PC and reduces assembly steps, space requirements, cost, and CO2 emissions, as the weight of the prototype can be reduced by up to 1.5 kg compared with conventional products. The key, however, is focusing on one plastic, as this can reduce the labor required to separate, sort, and store the material in recycling streams without sacrificing performance.

Covestro also offers more sustainable PC grades. These Makrolon RE products are climate neutral from cradle to Covestro’s factory gate, thanks to the use of renewable electricity for production and the introduction of raw materials derived from mass-balanced biowaste and residues.

In the future, lighting systems will be designed in such a way that they can be recycled at the highest possible value-added level. This includes reuse of entire assemblies. Covestro is supporting these developments as part of the Nalyses project, including the evaluation of technologies for materials recycling. The company is also responsible for characterizing and optimizing material properties and is working to extend the service life of headlights with the help of suitable materials.

The Nalyses research project looks at the entire value chain from raw materials to design and overall system requirements, as defined by car manufacturers such as BMW. The development and analysis of a digital twin ensures the assessment of recyclability and the carbon footprint at any stage of the development. process. In this way, less sustainable developments can be avoided even before design and production.

About the Author(s)

You May Also Like