Syensqo Expands Bio-based Epoxy Prepreg Portfolio

MTM 49-3 resin contains 30% bio-sourced monomers composite material and responds to sustainability goals in automotive.

March 4, 2024

At a Glance

- Enhanced toughness for superior impact resistance versus competitive thermoset prepregs

- High strength-to-weight ratio, yielding component mass savings of up to 40% over metals

- Fellow epoxy resin supplier Westlake secures ISCC Plus certification at its Duisburg, Germany, site

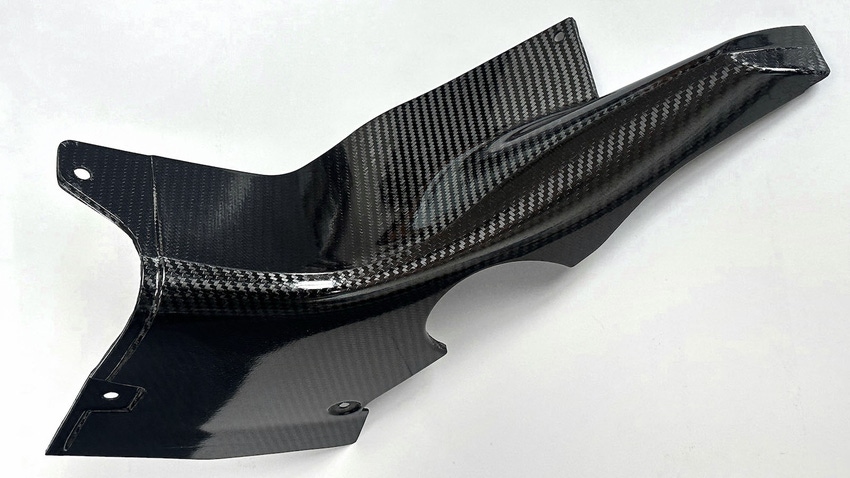

Syensqo, previously part of Solvay Group, has developed a new version of its flagship MTM 49-3 resin that contains 30% bio-sourced monomers. The new product variant complements the portfolio of the company’s MTM advanced prepregs, and targets structural automotive applications, including body panels, chassis components, and spoilers.

Material helps OEMS meet sustainability goals

“Our new bio-based MTM 49-3 will help OEMs and Tiers to reduce fossil depletion and meet their carbon-neutrality goals, while ensuring the same high levels of quality, processability, and mechanical performance as its original counterpart,” states Greg Kelly, head of Composite Product Management at Syensqo.

Just like the incumbent material, Syensqo’s new bio-based MTM 49-3 has a dry glass transition temperature (Tg) of 190°C, and it exhibits enhanced toughness for superior impact resistance versus competitive thermoset prepregs. Thanks to its high strength-to-weight ratio, it can yield up to 40% component mass savings over metals. The product is compatible with autoclave and press-conversion processes and achieves curing at 135°C within 60 minutes. In addition, it has been designed for operator safety, and is free from carcinogens, mutagens, or reproductive toxins.

Syensqo will officially introduce the bio-based MTM 49-3 to the market at JEC World 2024 in Paris this week at booth K58 in hall 5.

Westlake well-placed with German ISCC Plus certification

Another epoxy resin supplier is treading the sustainability route via International Sustainability & Carbon Plus (ISCC Plus) certification of its German site in Duisburg, Germany. This is the second Westlake Epoxy site in Europe to receive ISCC Plus certification. The goal is to achieve this certification for all Westlake Epoxy sites in Europe in the near future.

“This marks a significant step in Westlake Epoxy’s strategy to integrate renewable carbon materials into its raw material supply chain while reducing energy consumption and greenhouse gas emissions,” said Vice President – Epoxy, Ann Frederix. “The ISCC Plus certification creates opportunities for our customers to access a wider range of innovative renewable, attributed, and lower-carbon footprint products. The mass balancing concept ensures equivalent performance to traditional epoxy products while supporting our customers in fulfilling their sustainability objectives.”

Westlake Epoxy serves a broad variety of industries, including adhesives, aerospace, automotive, civil engineering and construction, composite and wind energy, electronics, electric laminates, marine, and protective coatings.

About the Author(s)

You May Also Like