Frigel introduces CT option, allowing Microgel Chiller/TCUs to operate seamlessly with open cooling towers

Intelligent process cooling provides plastics processors with the ability to leverage the chiller/TCUs to improve productivity, profitability and quality.

March 29, 2018

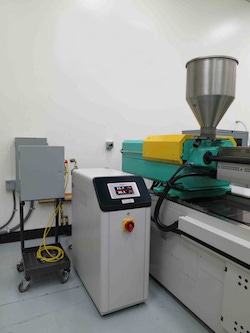

Frigel (East Dundee, IL) has announced that its line of Microgel combination Chiller/Temperature Control Units (TCUs) can now be configured with a CT option, allowing them to work seamlessly with open cooling towers. Intelligent process cooling provides plastics processors with the ability to leverage the chiller/TCUs for improved productivity, profitability and quality. The Microgel produces less scrap and can improve cycle time by as much as 20%, according to Frigel.

Frigel (East Dundee, IL) has announced that its line of Microgel combination Chiller/Temperature Control Units (TCUs) can now be configured with a CT option, allowing them to work seamlessly with open cooling towers. Intelligent process cooling provides plastics processors with the ability to leverage the chiller/TCUs for improved productivity, profitability and quality. The Microgel produces less scrap and can improve cycle time by as much as 20%, according to Frigel.

The CT option, one of several new Microgel innovations on display at booth W193 at NPE2018, filters out potential open-cooling tower water contaminants. Ideal for machine-side process cooling, the CT option also alerts users to potential problems with contaminated cooling-tower water to ensure maximum uptime of the chiller/TCU. Previously, Frigel recommended the use of Microgel units only with an Ecodry central cooling system, since it’s a closed-loop, clean-water system.

The CT option is available on the Microgel RCM, RCD and RCX models. Other options now available on the chiller/TCU and on display at NPE include:

External temperature sensors, which complement internal sensors for accurate temperature readouts/control at each mold to further optimize cooling temperatures for improved mold performance;

variable-frequency drives on the unit’s pumps, allowing them to deliver only the necessary amount of water pressure differential and flow needed for peak operating efficiency with the least amount of energy consumption; and

digital flow meters that provide an unprecedented level of accurate flow data, according to Frigel, to ensure optimal mold performance based on the unique characteristics of each tool.

According to Frigel North America Marketing Manager Al Fosco, the latest advances in the Microgel line of chiller/TCUs are designed to give plastics processors a clear-cut advantage in an increasingly competitive industry.

“Each processor and each application is unique,” Fosco said. “Some rely on open cooling towers for cooling water and some don’t. Most need very precise temperature control data. Some need exact pressure differentials based on a given mold. All need turbulent flow.

“It’s why we take a scientific approach when we analyze customer applications and configure a system to their exact needs. It’s the Frigel Diamond Service advantage, which ultimately gives them what they need to optimize productivity, profitability and quality,” he added.

Frigel’s presence at NPE 2018 extends beyond its own booth—32 Frigel units will be operating in 14 booths of leading plastics machinery manufacturers. Frigel claims this level of support is unprecedented for any process-cooling equipment company.

About the Author(s)

You May Also Like