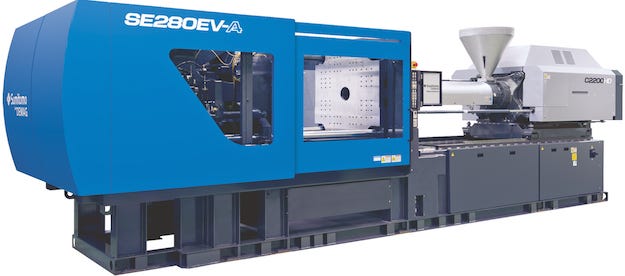

Sumitomo aims to change perception of mid-sized molding machines with new all-electric SEEV-A molders

For molders who continue to look for reduced cycle times, ease of mold installation and lower maintenance costs, Sumitomo (SHI) Demag (Schwaig, Germany) has introduced its new SEEV-A series of mid-sized, all-electric machines to the North American market.

January 6, 2016

For molders who continue to look for reduced cycle times, ease of mold installation and lower maintenance costs, Sumitomo (SHI) Demag (Schwaig, Germany) has introduced its new SEEV-A series of mid-sized, all-electric machines to the North American market.

SEEV-A machines, which come in eight model sizes ranging from 247 to 562 tons, bring the precision, productivity and profitability benefits of all-electric injection molding machine technology to applications with larger, heavier and more complex molds, according to Sumitomo (SHI) Demag. They efficiently handle higher injection requirements that typically would have been run on a hybrid or hydraulic machine and allow bigger parts to run on smaller machines.

Speak with Sumitomo (SHI) Demag and hundreds of other suppliers of equipment, products and services for advanced manufacturing at the co-located MD&M West and PLASTEC West events coming to Anaheim, CA, from Feb. 9 to 11, 2016.

"Sumitomo introduced its first mid-sized, all-electric machine in 1997, and today there are several other manufacturers with models in the 200- to 600-ton range," said John F. Martich III, Vice President and COO of Sumitomo Demag's U.S. operations. "But this machine series is profoundly different, and it opens up all-electric precision and profitability to a much wider range of molders and applications. It will end any perception of mid-sized all-electrics as being lightweight or unable to handle bigger, heavier molds."

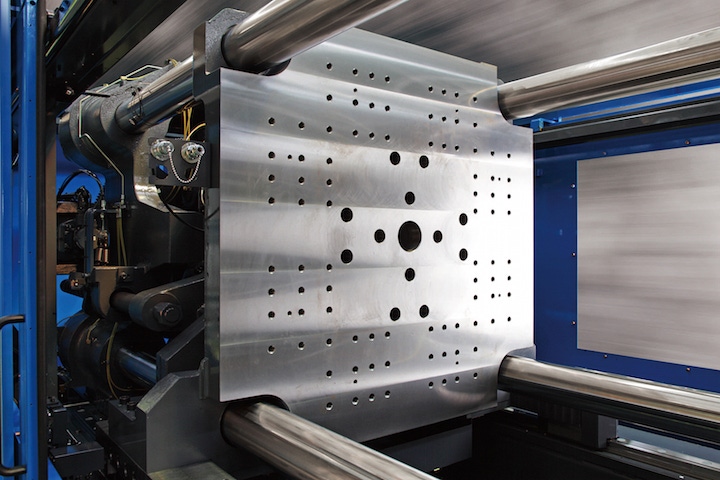

The SEEV-A combines "best-in-class" specifications with exclusive technologies that reduce injection and clamp force requirements, said Sumitomo. These increased specifications and design features can be found end-to-end on the SEEV-A. For example, the tie bar spacing was increased an average of 8% in the transverse direction and 15% in the longitudinal direction compared with the predecessor SE-HDZ series; it is the highest among machines of the same class. The square configuration of the tie bar spacing also allows molds to be loaded from the side.

Additionally, bushing-free tie bars keep the mold area clean and free of grease. The mold opening stroke is 25 mm wider than the predecessor model, and the ejector stroke is 220 mm for all model sizes, the largest among all machines of the same class.

Sumitomo Demag uses exclusive technologies in the new SEEV-A, including S-MOVE, which replaces multi-step, mold open/close speed settings with an optimized speed pattern that is both smoother and 15% faster, according to the company's information. This, combined with exceptionally fast clamp open/close speeds up to 56.6 in./s (1438 mm/s), can significantly shorten cycle times.

The SEEV-A also uses Z-Molding's Flow Front Control system to achieve complete and balanced filling with reduced injection pressure, and Z-Molding's Minimum Clamping Molding system to reduce clamp force requirements and ensure optimized venting of gases and flash-free molding, notes Sumitomo.

About the Author(s)

You May Also Like