Mold-Masters and ABBA launch PET preform tooling business

Hot runner supplier Mold-Masters and preform tooling supplier ABBA Systems are joining forces for a new venture that will offer complete polyethylene terephthalate (PET) preform molds. Operating under the brand name iPET Systems, the companies say their iPET molds and hot runners will feature a proprietary design and offer interchangeability with existing PET mold platforms.

September 15, 2009

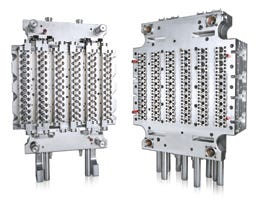

Hot runner supplier Mold-Masters and preform tooling supplier ABBA Systems are joining forces for a new venture that will offer complete polyethylene terephthalate (PET) preform molds. Operating under the brand name iPET Systems, the companies say their iPET molds and hot runners will feature a proprietary design and offer interchangeability with existing PET mold platforms. Launching the business at Drinktec 2009 (Munich, Germany), the company will offer molds, conversions, retrofits, refurbishments, spare parts, and service from five manufacturing locations and 40 sales and service offices globally. The website, www.iPETsystems.com, identifies three geographically based business units: iPET Americas, iPET Europe, and iPET Asia, with offices in Brantford, ON; São Paulo, Brazil; Baden-Baden, Germany; Bondoufle, France; Kunshan, China; and Kawasaki, Japan.

|

The systems are available from two to 192 cavities, with up to four positions of postmold cooling. iPET is also promoting what it calls new technology with advantages to preform molders, including a proprietary iFlow design that reduces pressure drop in the hot runner manifold, resulting in more uniform fill and less preferential shear stress compared to conventional gun-drilled manifolds. In addition, the valve gate has been purpose engineered for molding PET so it generates less PET dust, reduces crystallinity in the gate, and simplifies in-press service. Patented iCool technology reportedly allows iPET molds to cool more evenly and efficiently.

Manfred Lausenhammer, VP sales and engineering at ABBA Systems told PlasticsToday that the iCool and iFlow technologies were jointly developed by Mold-Masters and ABBA specifically for the iPET business to provide customers with improved performance over traditional systems. "We are convinced we have stack cooling and hot runner technology available which exceeds anything currently available on the market," Lausenhammer said. In aggregate, ABBA and Mold-Masters say these technologies result in preform molds that run faster, use less energy, change color quickly, run lower AA levels, produce higher uptimes, and are easy to service.

ABBA Systems was founded in 1993 in Brantford, ON, where it has an 18,000-ft2 site and

78 staff. The employee-owned company runs 24/6 operations, with sales split evenly among Canada, the U.S., and Europe. Mold-Masters Limited has more than 1600 granted and pending international patents in hot runner technology, supplying hot runner systems, temperature controllers, and complete hot halves, with a support network spanning more than 40 countries, and facilities in North America, South America, Europe, and the Pacific Rim. —Tony Deligio

About the Author(s)

You May Also Like