World Tour: True tints promised inline as extruders churn out compounds

Color accuracy is one of the most difficult problems facing color compounders and masterbatchers today. Slight tone variation can cause an entire batch to be off-spec and worthless.

June 5, 2009

Color accuracy is one of the most difficult problems facing color compounders and masterbatchers today. Slight tone variation can cause an entire batch to be off-spec and worthless.

A German company, Rapid Optical Control (ROC, Münster/Hesse, Germany) has come out with a development it says can change all that and save processors money to boot. Traditionally, compounders need to make a manual sampling during color compound production to check shade accuracy. The granules coming out of the pelletizer need to be injection molded into a color chip that is then checked by a spectrometer. Lab times before the results have been obtained vary between 25-40 minutes and the cost per measurement is generally €30-€60. In that time the processor has extruded a sizeable amount of scrap if the color is off.

|

Eckhard Siegmann, ROC technical director says his company’s ROC-ColorControl System can do it cheaper, better, and a lot faster. “Customers are not going to accept the slightest defect in a high quality branded product,” says Siegmann. “Color fluctuations remain a never-ending story for compounders who find corrections time-intensive; they lower efficiency, and produce off-spec materials that often are disposed of as waste.”

His fully automatic, inline device, recently demonstrated during a trade public open house at extrusion equipment maker Coperion (ex-Werner & Pfleiderer; Stuttgart, Germany), takes samples just after the water bath and granulator. The ROC-ContiSampling System loads granules into a kind of pneumatic or tubular post system to transport them to the ROC-ColorControl unit. Transport distances of more than 200m are possible. Granules are spread on a temperature controlled sample tray, where a multispectral camera scans the samples. About 4 million pixels (an average of 1500 pixels/granule) are assessed with reflectance spectra. The image processing system can filter out shadows and stress whitening zones. The measurement area is approximately 50 by 500 mm, while the spectral resolution is 400-700 nm in 10-nm intervals.

|

Unlike traditional systems that may only assess one measurement spectrum of a single round spot, the ROC-ColorControl issues its results based on thousands of spectra in CIE-Lab values. Measurement takes 2.5-3 minutes and only requires 35 ml of pellets. Up to six production lines can be monitored using one ROC device. Cost per measurement: €2-€3. Admittedly the device doesn’t solve all problems. It can’t measure powders and it is intended for strand and underwater pellets. Company owner Peter Dietrich says so far the unit can measure opaque colors rather than translucent or effect colors.

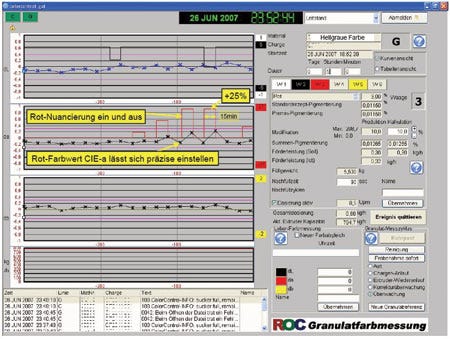

Once the evaluation has been returned to the compounding extruder, the semi-automatic ROC-ColorCorrect System goes into action if the initial color is off. Single-pigment concentrates (SPC), generally in addition levels of 0.2-2.0 kg/hr, are used for corrections. Dietrich says white and black SPCs are sufficient for 50% of all corrections but use of blue, yellow, green, and red pigments in corrections is also possible. Existing production lines can be retrofitted with small-quantity gravimetric dosage equipment for this.

Software depicts the color shade addition graphically together with color measurement values. This way the operator sees the success of a corrective step immediately, says Dietrich. “Small compounding orders of 1000 kg or less can now be produced profitably as color correction time can be slashed by up to 80%,” says Siegmann. Investment payback is said to be less than one year. All color samples and color corrections are documented regarding color, shape, and standard deviation.

Siegmann gives the example of a small-batch specialty compounder churning out orders of 1000 kg or less in a year (6000 hours). A production line using a common spectrometer/injection molded chip system will produce 818 orders while with the ROC-ColorControl system, 1302 orders, a 60% increase in output, can be extruded due to longer production time. —[email protected]

About the Author(s)

You May Also Like