DuPont boosts Zytel production capacity in Europe

DuPont Performance Polymers (Wilmington, Delaware) has increased production capacity of its Zytel PA 66 and PA 6 product at the Uentrop facility in Hamm, Germany, by 20%. The reason, according to the company, was in order to meet growing demand “primarily in the global automotive industry.”

June 16, 2015

DuPont Performance Polymers (Wilmington, Delaware) has increased production capacity of its Zytel PA 66 and PA 6 product at the Uentrop facility in Hamm, Germany, by 20%. The reason, according to the company, was in order to meet growing demand “primarily in the global automotive industry.”

Lightweight, high-performance Zytel nylon often replaces metal in automotive applications. It is used to make a wide range of components, such as air ducts, engine covers, charged air coolers, transmission components and radiator end tanks. In electrical and electronic systems, Zytel nylon is widely used in enclosures, sockets, terminal blocks, circuit breakers, switches and relays.

Zytel enables both the total cost and weight of components to be reduced, thus contributing importantly to industry efforts to improve fuel efficiency, lower CO2 emissions and enable sustainable mobility.

|

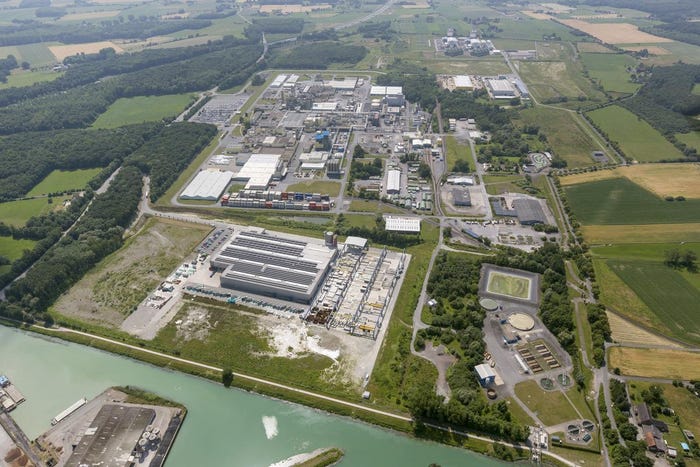

DuPont Uentrop Facility in Hamm, Germany. |

“Nylon continues to be the starting point for many product designers because it’s versatile, easy to mold and offers exceptional long-term performance in the most challenging environments,” said Richard Mayo, Global Business Director for the nylon businesses in DuPont Performance Polymers. “In many ways, nylon defined the category of Engineering Polymers and continues to redefine where plastics can go in the future.”

Having invented nylon 66 back in 1935, DuPont has since grown into the largest, most globally networked nylon manufacturer focused on the engineering polymers market. It owns and operates world-scale, continuous-polymerization assets for nylon in all three regions of the world and operates compounding sites in 13 countries to ensure local supply wherever customers are located. Uentrop is its largest nylon production facility in Europe.

“We continually work to optimize and refresh our nylon product line, delivering innovative materials and solutions to meet the needs of our customers and the markets they serve,” said Mayo. “It’s this attention to matching the portfolio to customer’s needs that has helped us build the world’s broadest portfolio of nylon products and continue to expand that offering.”

About the Author(s)

You May Also Like