At Euromold, 3D printing was literally huge

Among the many developments in additive manufacturing technology on show at last week's Euromold were two machines that demonstrated just how big 3D printing is becoming. Built by the Berlin-based startup company Big Rep and by Opiliones 3D, a recently formed company by a group of Dutch mechanical engineers, these printers were hard to overlook.

December 4, 2014

Among the many developments in additive manufacturing technology on show at last week's Euromold were two machines that demonstrated just how big 3D printing is becoming. Built by the Berlin-based startup company Big Rep and by Opiliones 3D, a recently formed company by a group of Dutch mechanical engineers, these printers were hard to overlook.

The Opiliones printer was the odder-looking of the two - the name means "daddy-long-legs" in Latin, which it resembles. "The printer is basically a deltabot with a Rostock design," said Peter Sluiter of Opiliones. The design uses parallelograms in the arms to restrict the movement of the end effector to movement in the X, Y or Z direction: in other words, a vertical linear motion is used instead of rotation. The printer consists of three vertical columns (two steel tubes per column), arranged in an equilateral circle, on which carriages move up and down. The carriages are connected to three effector arms, which are connected to the end effector. "It's fascinating to watch," Sluiter said. In fact, the movement of the printer is mesmerizing.

|

The Opiliones printer |

The filament supply is directly coupled to the hot-end, resulting in a very direct response and making filament switches and cleaning fast and easy. Built with magnetic clamping of all the moving parts (i.e., no play), the printer comes in two sizes, and is targeted at the home use and prototyping market. The largest model offers a printing surface of 500 mm and a maximum print height of 745 mm. "But this can be easily scaled up," Sluiter explained.

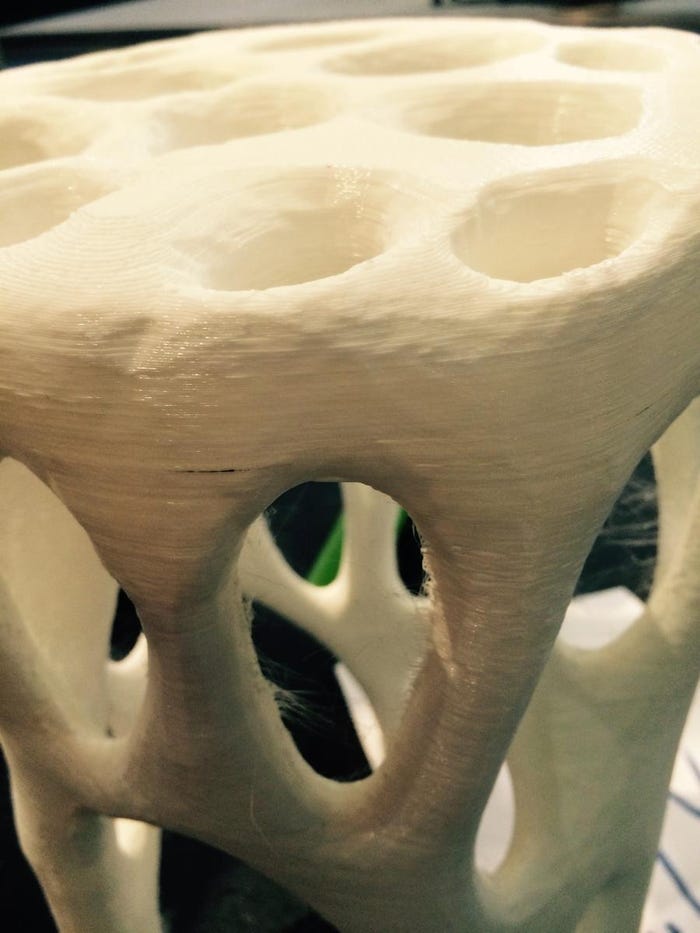

Samples of products printed by the printer were also on display at the Opiliones stand, one of which had to be the weirdest product - by far - at the show: a stool that on closer inspection seemed to be slightly hairy at the edges. It was: Dutch artist Eric Klarenbeek who had been exploring ways of 3D-printing living organisms, such as mycelium, designed and printed the stool from PLA, incorporating mushroom mycelium, which was starting to sprout. When full-grown and dried, it turns into a structural, stable and renewable material. "The artist calls it living furniture," Sluiter said. Indeed.

|

Mushroom stool - you can see it is starting to sprout! |

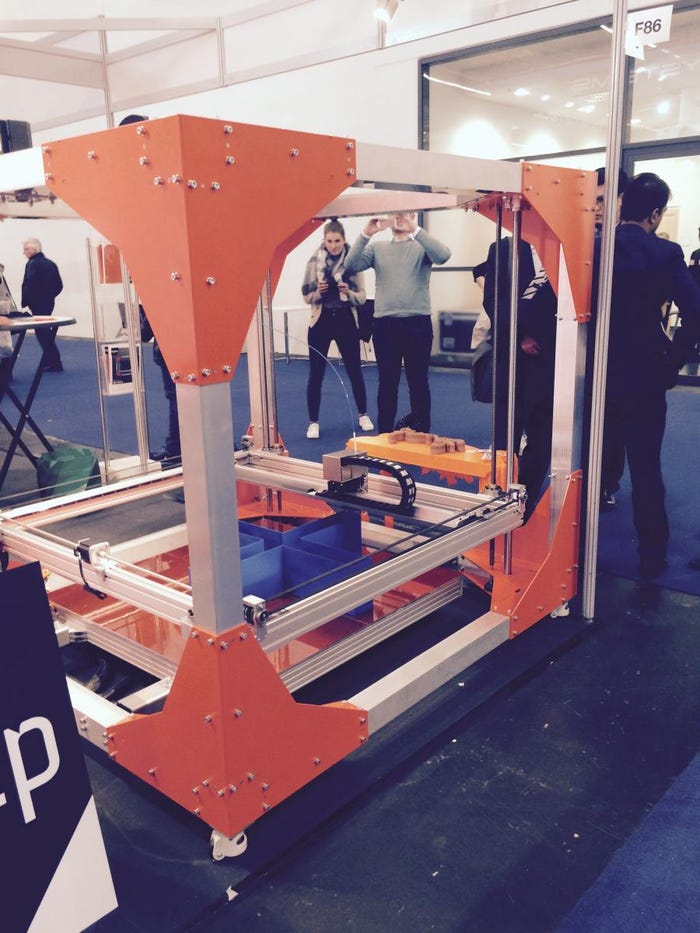

And then there was the BigRep One.2 3D printer: huge, orange colored, with an aluminum frame and a 1.3 m3 working volume, this is the printer that can print prototypes and models on a 1:1 scale, or even designer furniture. An orange baroque side table was on display at the stand to demonstrate just how large the objects this printer can print can be. It's the biggest FDM printer in the world and, according to its makers, will "revolutionize manufacturing and make it more flexible."

|

BigRep One.2 3D printer |

Built by BigRep, a company founded only 11 months ago, the BigRep One.2 is based on fused filament fabrication technology; the print head, which is basically a thermoplastic extruder, deposits molten plastic as a thin thread. Each thread is thermally fused with the next thread, line by line. According to the company, the printer has 27 times the volume of a large desktop 3D printer, but costs only about five times as much as the biggest desktop machine. As Lukas Oehmigen, CTO and founder of BigRep said: "With our latest project we are demonstrating, how 3D printing can be used in manufacturing. Our objective is to make full-size 3D printing affordable for everyone - in design, prototyping and manufacturing. In this class, we are setting the standards."

Having just successfully raised its first round of financing, BigRep is currently developing an ecosystem for 3D printing consisting of full scale printers, a cloud print service connecting thousands of printers globally, enabling localized manufacturing, and innovative printable materials for industrial and professional use. "BigRep's affordable large-format printers and customer solutions such as BigRep Industrial Cloud Printing, surges forth to a new dimension in this promising technology," says CEO René Gurka. " Since we started our business in the beginning of 2014, we have been literally flooded with requests and inquiries. Our new shareholders not only support us with capital, but more importantly, they provide knowledge to foster the expansion of our R&D, production and sales."

Which means that the way it looks now, BigRep is only going to get a lot bigger - in every sense.

|

BigRep baroque table |

About the Author(s)

You May Also Like