KraussMaffei Berstorff shows extruders with a small footprint and big performance at K2016

July 5, 2016

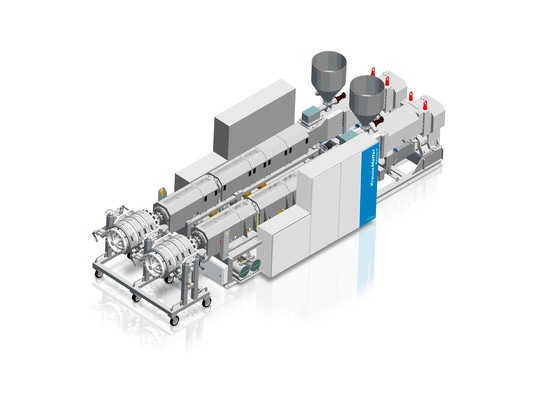

Among the exhibits at the KraussMaffei Berstorff booth at K 2016 this October in Düsseldorf, the custom solution for the 36D twin-screw extruder series, designed for high-performance extrusion of U-PVC pipes, will stand apart as a perfect demonstration of intelligent and individualized systems engineering. A combination of two KMD 108-36 E2/R twin-screw extruders able to produce PVC-U pipes at a throughput of up to 2000 kg/h will be on display – a feat made possible by the high overall system efficiency (OEE) with its process technology features that are designed to increase output.

Among the exhibits at the KraussMaffei Berstorff booth at K 2016 this October in Düsseldorf, the custom solution for the 36D twin-screw extruder series, designed for high-performance extrusion of U-PVC pipes, will stand apart as a perfect demonstration of intelligent and individualized systems engineering. A combination of two KMD 108-36 E2/R twin-screw extruders able to produce PVC-U pipes at a throughput of up to 2000 kg/h will be on display – a feat made possible by the high overall system efficiency (OEE) with its process technology features that are designed to increase output.

"We not only distinguish ourselves with our high level of expertise as a system provider, but also are in demand as a capable partner for customized systems engineering," said Peter Roos, President of the Extrusion Technology Segment and of the KraussMaffei Berstorff brand. “Our featured product is an optimal implementation of our customers' requirements for increased performance while simultaneously minimizing the space requirements.”

By combining two KMD 108-36 E2/R twin-screw extruders, the amount of space required is reduced about one-third, which means a high production output even when space is limited.

"This system is of particular interest to processors who manufacture U-PVC standard pipes in large quantities and must place particular focus on cost-effectiveness. Higher output with a smaller footprint cuts production costs over the long term," says Roos, describing the extruder combination.

The main focus is on the long, effective preheating length, which ensures a balanced combination of shearing energy and heating energy, optimal material processing and hence excellent melt homogeneity - in addition to low compression values in the area of the throttle zones. Optimal wear-resistance is guaranteed by the deep-nitrided barrels and the molybdenum welded layer on the screw threads, which allow even higher-filled PVC compounds to be optimally processed.

Significant energy-savings are another benefit. The energy requirements are lower compared to a larger extruder that uses the twin-strand. The high-performance combination saves 0.02 kW per h/kg of material throughput compared to a KMD 164-32/R.

The featured product is part of an exemplary combination with the KM-RK 23-250 pipe head, a model from the newly designed pipe head generation designed for a very large diameter range with very high outputs. Due to its design features such as flow channel volume and mandrel ridges configured for optimum flow, the pipe head is ideally suited for high-performance extrusion with consistently high quality.

KraussMaffei Berstorff can be found in Hall 15, Booth B27/C24/C27/D24 at K 2016.

About the Author(s)

You May Also Like