Fluoro-LSRs deliver processing efficiency for fuel-resistant auto components

Building on its elastomer technology in fluoro liquid silicone rubber (F-LSR), Dow Corning Corporation (Midland, MI) is introducing two new Silastic brand F-LSRs to expand design options and provide processing efficiency for fuel-resistant automotive components.

July 16, 2014

Building on its elastomer technology in fluoro liquid silicone rubber (F-LSR), Dow Corning Corporation (Midland, MI) is introducing two new Silastic brand F-LSRs to expand design options and provide processing efficiency for fuel-resistant automotive components. The newest product offerings add 60 and 70 durometer hardness options to a growing family of fully and partially fluorinated liquid silicone rubbers - a portfolio whose size is unmatched by any other fluorosilicone elastomer supplier. Fluoro-LSRs target fuel-resistant automotive componentsReportedly meeting market needs for both performance and cost control,

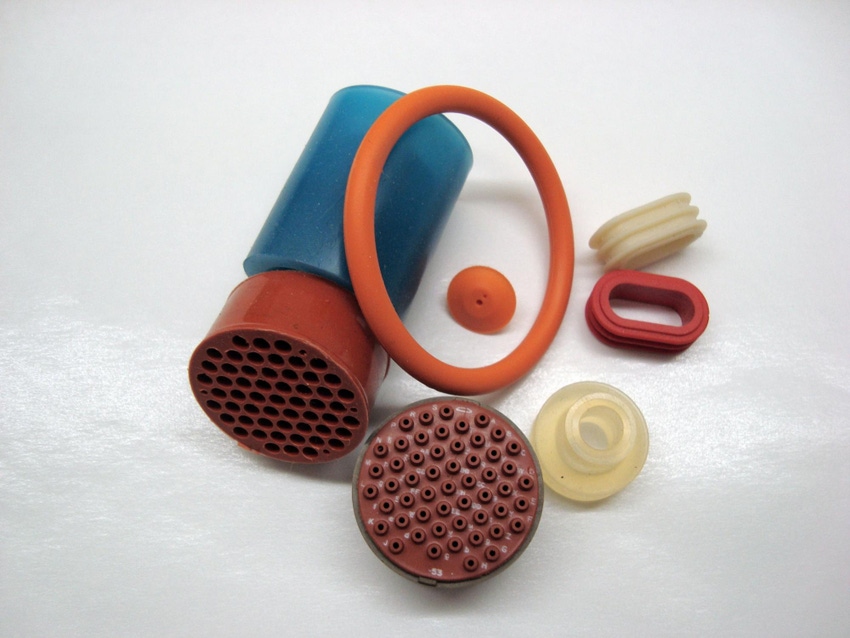

Fluoro-LSRs target fuel-resistant automotive componentsReportedly meeting market needs for both performance and cost control, Silastic F-LSRs are said to combine the fuel, oil and solvent resistance of fluorosilicone rubber (FSR) with the processing benefits of liquid silicone rubber (LSR). This latest fluorosilicone elastomer technology from Dow Corning can help designers develop more durable components for withstanding severe operating environments and can help fabricators achieve manufacturing improvements with automated processing, reduced labor costs, shorter cycle times, energy savings and reduced scrap rates. Dow Corning is well-prepared to meet growing market needs with a full range of FSR and F-LSR products."These new Silastic F-LSR products give designers added flexibility for meeting critical performance requirements on small, intricate high-precision or over-molded parts that must withstand harsh service conditions," says Gabe Knee, Automotive Market Leader for Dow Corning. "And, the Silastic F-LSR technology offers fabricators substantial process gains for producing newer seals, gaskets, connectors, flexible diaphragms, membranes and valves using standard injection molding equipment."The two newest

Silastic fluoro liquid silicone rubbers (PDF) in Dow Corning's product range are

Silastic FL 60-9201 F-LSR (60 Shore A durometer) and

Silastic FL 70-9201 F-LSR (70 Shore A durometer). Both exhibit excellent resistance to nonpolar hydrocarbon fuels, oils and solvents and offer process cost savings, especially for molding small parts in high volumes. Silastic FL-60-9201 F-LSR provides excellent flexibility for dynamic seals such as diaphragms and membranes, while Silastic FL 70-9201 F-LSR provides high modulus with low compression set for static seals such as O-rings and gaskets.The new hardness options join Dow Corning's other fully fluorinated (30 and 40 Shore A) and partially fluorinated (45 and 65 Shore A) liquid silicone rubbers. Designers can choose from a full range of excellent performance properties to meet specific application requirements. Fabricators reportedly benefit with optimized rheology for easier molding of intricate parts, fast cure profiles for shorter cycle times, reduced flash and scrap, enhanced dimensional stability, and lower processing temperatures for over-molding of plastic parts."Increased performance, cost control and meeting regulatory requirements are critical design objectives throughout today's transportation industry worldwide," Knee says. "Dow Corning anticipates a growing need for fluorosilicones. And, our two newest Silastic F-LSRs can help OEMs improve component performance and reliability in key systems for fuel economy and emissions control, as well as help fabricators increase efficiency, reduce material waste and possibly gain significant process savings."

About the Author(s)

You May Also Like