Food waste and packaging: Fighting negative perceptions while continuing to innovate

Sell-by. Best-before. Use-by.Those ever-prevalent labels on perishable packaged foods are often used as a barometer to determine when to throw out the food product. As it turns out, these labels are only advisory and just define the last date recommended for the use of the product while at peak quality.

March 14, 2013

Sell-by. Best-before. Use-by.

Those ever-prevalent labels on perishable packaged foods are often used as a barometer to determine when to throw out the food product. As it turns out, these labels are only advisory and just define the last date recommended for the use of the product while at peak quality.

However, approximately 60% of household food waste arises from products "not used in time," according to UK's Waste and Resources Action Program (WRAP).

However, approximately 60% of household food waste arises from products "not used in time," according to UK's Waste and Resources Action Program (WRAP).

The sell-by date is a cautious estimate at best, but other than the standby nose test, how can one know if the food is still safe to eat or not? Well, university researchers in Europe hope a new plastic sensor, together with packaging, can help to solve this issue.

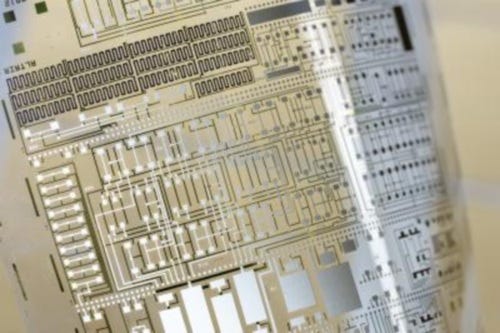

Researchers at Eindhoven University of Technology, Universitá di Catania, CEA-Liten and STMicroelectronics have invented a plastic analog-digital converter to fight food waste. The researchers say that producers could include an electronic sensor circuit on their packaging and using a scanner or a mobile phone can monitor the acidity level of the food, show the freshness of a steak or whether frozen food was defrosted.

Researcher Eugenio Cantatore with the Eindhoven University of Technology told PlasticsToday there is already a widespread research effort on monitoring food quality using advanced silicon-based sensors, but the problem is that this kind of technology can be costly when applied to each food item.

"If each packaged item must be controlled so that the end user can check the results, a much cheaper solution is needed," he said. "We, together with our partners, make electronics on the same plastic foils that are used already for packaging because we use very low temperature processes. Moreover, we use mostly printing techniques, which are fast and do not waste material. All this holds the promise for cheaper solution than conventional silicon-based electronics."

The plastic semiconductor can even be printed on all kinds of flexible surfaces, which Cantatore says makes it cheaper to use.

The researchers have succeeded in making two different plastic ADCs. Each converts analog signals, such as the output value measured by a sensor, into digital form. One of these new devices is the very first printed ADC ever made.

A sensor circuit consists of four components: the sensor, an amplifier, an ADC to digitize the signal and a radio  transmitter that sends the signal to a base station. The plastic ADC was the missing link; the other three components already exist, Cantatore said.

transmitter that sends the signal to a base station. The plastic ADC was the missing link; the other three components already exist, Cantatore said.

Now researchers are working on the integration of the full electronic chain and Cantatore estimates it will take at least five years before we can see this device on supermarket shelves.

He said this technology had spurred interest in the semiconductor arena and they hope to receive interest from the food and distribution industry.

"Expiration based on direct measurements using sensor in packaging could be much more accurate in ensuring food safety and at the same time less waste," he said.

Market opportunities for plastic manufacturers

In a world of seven billion people, set to grow to nine billion by 2050, about one-third of all food produced, worth around $1 trillion, gets lost or wasted in food production and consumption systems, according to data released by the Food and Agriculture Organization (FAO) of the United Nations.

Food waste is a problem in industrialized countries, caused by both retailers and consumers throwing perfectly edible foodstuffs into the trash. At the food manufacturing and retail levels, large quantities of food are wasted due to inefficient practices, quality standards that over-emphasize appearance, confusion over date labels, and consumers being quick to throw away edible food due to over-buying, inappropriate storage and preparing meals that are too large.

In developing countries, roughly 95% of food loss and waste are unintentional losses at the early stages of the food supply. The study cited inadequate harvest techniques, poor post-harvest management and logistics to a lack of suitable infrastructure, processing and packaging.

In developing countries, roughly 95% of food loss and waste are unintentional losses at the early stages of the food supply. The study cited inadequate harvest techniques, poor post-harvest management and logistics to a lack of suitable infrastructure, processing and packaging.

"When we look at food loss, one of the big problems in developing countries is the lack of a modern packaging system," said Keith Christman, managing director of plastic markets for the American Chemistry Council (ACC). "It's important to start with the idea that we need to protect the product and the increased recognition that getting that product safety to the customers has to be the primary goal."

The British Plastics Federation (BPF) believes that not only can plastic packaging help prevent food waste, but it also provides significant overseas business opportunities for UK plastics packaging manufacturers.

The Institution of Mechanical Engineers report highlighted the need for innovative new technology in developing countries to help decrease food wastage, as current packaging and storage solutions in developing nations need improvement.

"The opportunity is there for the taking, I think some of our members have, but more should look into it," said Philip Law, the public and industrial affairs director for the BPF. "Certainly in overseas markets where they haven't got access to sophisticated packaging technology, UK companies have an advantage of not only to export packaging technology but also look into joint ventures and develop new plants in these territories."

For example in India about 21 million tonnes of wheat annually perishes due to inadequate storage and distribution, equivalent to the entire production of Australia, according to the Institution of Mechanical Engineers report. Packaging currently accounts for the largest consumption of plastics in India, at 24% of overall consumption.

The BPF said that the Indian government has signaled a willingness to open up its market to major foreign retailer investment highlighting the need for external parties to bring in new technology such as cold chain logistics systems, warehousing facilities and packaging technology.

"In India, legislation has recently changed to permit the deployment of supermarket retailing," Law said. "In the UK, we have a lot of experiencing in serving a sophisticated supermarket system, these companies here are well positioned to take advantage of that opportunity in India."

Perception vs. reality

A new report from WRAP, in partnership with the Industry Council for Packaging and the Environment (INCPEN), The Packaging Federation, Food and Drink Federation (FDF), Kent Waste Partnership and British Retail Consortium (BRC) claimed that consumers do not realize the role packaging plays in helping to reducing food waste.

While there is recognition that packaging is important to protect food on its way to, and in, the store, only 13% of consumers believe that it can play the same role at home, the report stated.

of consumers believe that it can play the same role at home, the report stated.

Despite continued packaging innovation to extend in-home life, through the use of intelligent materials, vacuum-packing and more recloseable packs, most consumers still believe that keeping food in packaging at home leads to it spoiling more quickly.

"People are seldom aware of the stresses and strains that a product has to survive so they don't think about how it needs to be protected," said Jane Bickerstaffe, director of INCPEN. "One of INCPEN's roles is to explain what packaging does. A telling fact is that ten times more resources - materials, energy, water - are used to make and distribute food than are used to make the packaging to protect it."

Alan Davey, director of innovation at Linpac Packaging, said the sector has been overshadowed by myths about the impact plastic has on the environment. He said Linpac is committed to challenging these perceptions by working closely with trade bodies such as INCPEN, EuPC, EuPR, Wrap and The Packaging Federation, government agencies and customers to "inform and educate them about the real environmental impact and the benefits of plastic packaging products."

Jeff Wooster, Dow's global sustainability leader for plastics, believes those who criticize packaging may not understand the important role packaging plays in protecting the food supply.

"They don't consider the impact if you take packaging away and the item now has a shorter shelf life - how much of that product will end up thrown away," he said. "There are benefits to the entire economy, society and the environment by using the right kind of food packaging to avoid having to throw away food that otherwise would be perfectly good."

Balancing sustainability with functionality

The ideal packaging is 100% product protection, and while there is a trend for material reduction, inadequate packaging can contribute to the waste of the product.

"When we think about packaging, we think about what is the best package to use - the one that protects the product and uses minimal resources and still delivers all the product protection we need," Wooster said.

Davey said that Linpac has an ultimate objective of developing products that use the minimum amount of material needed for packaging to effectively protect, preserve and present food. He said the company has made a considerable investment in time and expertise to ensure that all of its packaging, but particularly its most recent ranges, are designed using the minimum amount of raw material while still delivering a pack that achieves on functionality and has the qualities that meet the needs of the food product within.

"Yet, fundamental to the company's strategy to mitigate carbon is ensuring that new product innovations retain the qualities that make them fit for purpose," Davey said. "The consequences of a pack which does not achieve on functionality are more far-reaching. If a little extra packaging prevents food waste, this can dramatically reduce the amount of resources and energy used overall."

While there is no clear-cut answer on how to solve the global food waste issue, the global packaging industry continues to work on advancing the space.

"There's constant innovation, hot fill plastics, microwaveable plastics, modified atmosphere packaging, ethylene and oxygen scavengers, to protect food in the supply chain," INCPEN's Bickerstaffe said. "Offering consumers a range of portion sizes so they can buy just the right amount; providing instructions on how to store and to use food; designing containers so that all the food can be removed - we are looking at commissioning a piece of work on this. We are also looking at damage to food in the retail supply chain to identify how packaging can help reduce waste there. "

Read Part 1 of PlasticsToday's packaging to reduce food waste report.

About the Author(s)

You May Also Like