Genesis begins new collaboration with plastic compounds’ supplier

Last October contract manufacturer Genesis Plastics Welding formed a collaboration with plastics compounder PolyOne to optimize radio frequency (RF) plastics welding of that supplier's thermoplastic elastomers, with an eye on the medical device industry. This month Genesis announced a second such collaboration, this time with plastics compounder Teknor Apex, but again focused on TPEs and the medical market.

June 22, 2011

Last October contract manufacturer Genesis Plastics Welding formed a collaboration with plastics compounder PolyOne to optimize radio frequency (RF) plastics welding of that supplier's thermoplastic elastomers, with an eye on the medical device industry. This month Genesis announced a second such collaboration, this time with plastics compounder Teknor Apex, but again focused on TPEs and the medical market.

|

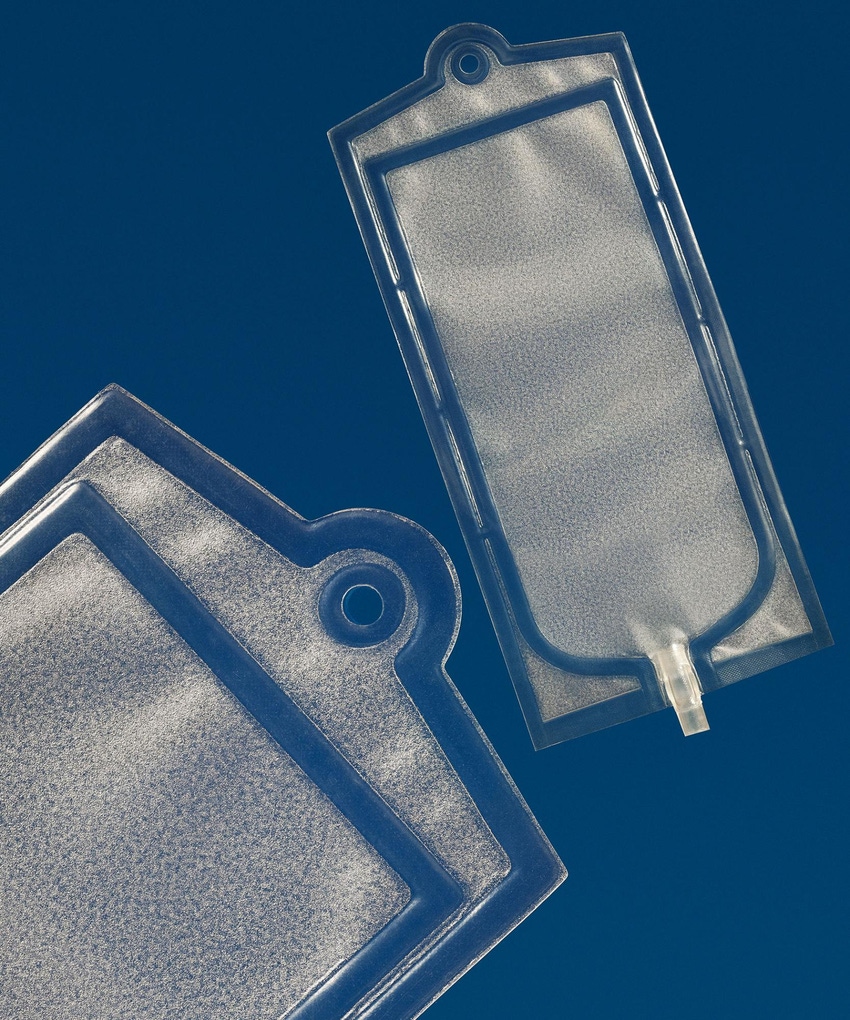

The two officially announced their collaboration earlier this month during the MD&M East trade show in New York. As in the work with PolyOne, Genesis' ecoGenesis RF plastics welding technology is the basis for the work. The technology facilitates manufacturing of medical bags and pouches made of TPEs. Older RF-welding techniques were restricted to high-dielectric-loss materials; low-dielectric-loss TPE could only be heat sealed, limiting configurations to straight lines. Polyvinyl chloride (PVC), which is the established material for medical fluid-delivery applications, has been under increased scrutiny over concerns with plasticizers.

Teknor Apex markets its medical-grade TPEs under the Medalist brand name. The ecoGenesis welding technology enables film extruded from the Medalist elastomers to form strong permanent bonds with itself as well as with polypropylene and similar polymers.

The compounder notes that in contrast to PVC, its Medalist elastomers are available at lower hardness ranges, provide a broader processing window, exhibit greater elasticity and superior low-temperature flexibility, have a wider range of service temperatures, and save weight because of their lower density. The elastomers are available in fully transparent grades.

Medical devices OEMs can either task Genesis (Fortville, IN) for its contract manufacturing services, or license the ecoGenesis technology for use on their own standard RF welding equipment.

About the Author(s)

You May Also Like