Manufacturers Lean into Automation, AI to Fill Skilled Worker Gap, Survey Says

In a poll of hundreds of US manufacturers, 85% said they have adopted or plan to adopt artificial intelligence (AI) to improve productivity.

June 21, 2023

Manufacturers of all stripes continue to wrestle with a shortage of skilled engineering talent, but the show, if you will, must go on, and 93% of manufacturing leaders are finding ways to address that gap, according to the eighth annual State of Manufacturing Report by custom manufacturing hub Fictiv.

The 2023 report, which compiles the results of a survey of hundreds of manufacturing companies across the United States, found that artificial intelligence (AI) is one of the new technology solutions expected to be leveraged to overcome the talent shortage.

|

In fact, 85% of those surveyed plan to adopt or already have adopted AI to improve efficiency and productivity, the report noted. And 97% of manufacturing leaders expect AI to influence product development and manufacturing functions.

Accelerating new product innovation is another significant focus of manufacturing leadership, with 49% of decision makers shifting their strategies on that front — an 11% increase over 2022.

The plastics industry, in particular, is embracing multiple technologies to improve efficiency and productivity on the production line, said Fictiv CEO and co-founder Dave Evans. “Robotics, IoT [internet of things] technologies, and AI are at the top of my list.”

Robots are already being widely used, he explained.

“Our State of Manufacturing Report shows that 89% of all manufacturing companies are already using or are implementing advanced industrial robotics. Plastics manufacturers, in particular, are using robots for material handling, assembly, sonic welding, and parts inspection, where their strength, repeatability, and precision capabilities are best leveraged.

“IoT is also seeing widespread adoption in conjunction with processing machines, whether with injection and blow molding or extrusion equipment,” said Evans, citing the use of sensors and monitoring systems to control flow, temperature, cooling, and trimming to ensure that “high-quality and consistent parts can be produced in large quantities.”

Meanwhile, AI “is already playing a significant role in plastics manufacturing — optimizing production processes and preventing down time. Machine learning, notably, is widely used to detect defects in conjunction with IoT devices; anticipate equipment failure and enable predictive maintenance; identify and reduce waste on the production line; and improve product quality.”

|

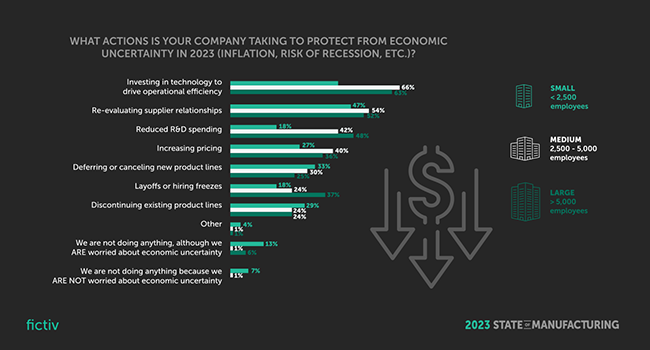

Two-thirds of mid-size manufacturers polled said they are protecting themselves from economic uncertainty by investing in technology to drive operational efficiency. |

Evans acknowledges that automation usually requires a significant up-front investment and advises plastics manufacturers “to look at robotics and other automation technologies as a means to do more with the equipment they currently have. They need to be mindful that the cost isn’t just in the equipment,” he added. “It’s also critical to invest in training existing employees to successfully integrate, monitor, and maintain the automation systems.”

That said, the “cost of automation is becoming more competitive as these technologies continue to develop and more companies use them” to address their labor shortages,” said Evans.

The full 2023 State of Manufacturing Report is available for download.

About the Author(s)

You May Also Like