Absolute Haitian Announces Availability of Servo-Hydraulic Multi-Component Presses

Designed to complement the Zhafir electric injection molders introduced in 2021, the machines feature clamping forces ranging from 67 to 2,709 tons.

July 5, 2022

Absolute Haitian has announced the availability of new servo-hydraulic multi-component injection molding machines that complement its Zhafir electric presses introduced in 2021. Based on its two popular servo-hydraulic series, the Mars III Multi and two-platen Jupiter III Multi series range from 67 to 2,709 tons of clamp force.

The machine design leverages Haitian’s accumulated knowledge of multi-component technology gained from the previous Iapetus generation of multi-component machines, said the company. The MA III Multi and JU III Multi reportedly are more efficient and offer increased configurations and flexibility than the Iapetus series. “Our goal is to advance Haitian’s long-standing and highly successful strategy of extending its product line and leveraging its manufacturing scale to deliver more machine configurations at competitive price points, thereby helping customers realize cost reduction,” said Sherman McGinnis, Vice President of Sales for Absolute Haitian.

|

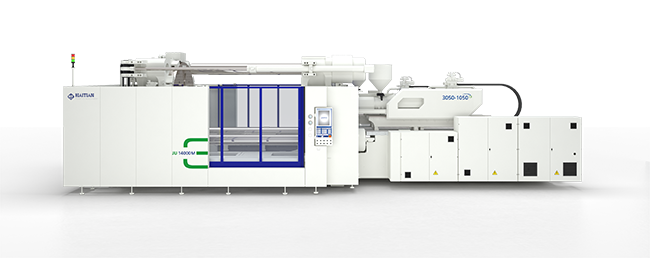

The JU III Multi injection molding machine series is available with clamping forces ranging from 843 to 2,079 tons. |

The new MA III Multi and JU III Multi machines are managed by the latest KEBA control technology, ensuring easy integration into upstream and downstream automation production processes. Features of the MA III Multi and JU III Multi machines include:

Horizontal “L”, vertical, and parallel configurations as well as piggyback placement of the second injection unit;

clamping forces from 1,200 to 5,300 kN (135 to 596 tons) in the MA III Multi and 7,500 to 18,500 kN (843 to 2,079 tons) in the JU III Multi;

shot sizes ranging from 19 to 1,295 grams (0.67 to 45.7 ounces) in the MA III Multi and 228 to 2,547 grams (43.3 to 89.8 ounces) in the JU III Multi;

the ability to switch off or remove the second injection unit so that the machine can run single-shot applications;

generous tie-bar specs and a strong load-bearing rotary table on the movable platen that accommodate large molds and provide capacity for stable production;

Connectivity Plus capability to support interaction with peripherals, automation, and integration with MES systems.

You May Also Like