An "Xten-sive" look at life as an American molder: Chapter 2

This second article in our four-part series focuses on significantly reducing material consumption, sustainability, and making Xten Industries' plant more efficient. The moves result in savings in a number of areas. (Ed: You can read the first instalment here.)

June 10, 2010

This second article in our four-part series focuses on significantly reducing material consumption, sustainability, and making Xten Industries' plant more efficient. The moves result in savings in a number of areas. (Ed: You can read the first instalment here.)

Custom molder Xten's focus for more than a year has been on sustainability, energy savings, and eliminating waste in nearly every area of its operations. One of the key issues in this area was material usage, with Xten deciding to look hard at its scrap and regrind.

|

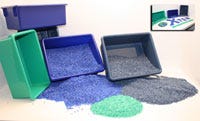

In the warehouse, Xten continues its efforts to use/switch over to reusable containers. |

|

Oil recycled from Xten's operations adds to the company's bottom line. |

|

Production manager Rob Korpela (right) and material handler Jose de la Mora perform a quality check on PC regrind. |

|

These bins are just one example of products Xten manufactures using regrind. |

Rob Korpela, production manager for Xten (Kenosha, WI), says that one of the company's goals is to reduce the amount of regrind sold. "We used to do a lot of grinding on the floor in the production area, which caused a lot of contamination, dust, and noise," Korpela says. "We created a separate grinding area so that we can turn our scrap into usable material, package it, and reuse it in the future. Now, when we grind materials at the press, we feed it back into the loader; otherwise, we grind things up in the back."

Educating customers about using regrind in their products is part of the company's material savings. Xten's planner, Tina McDonie, identifies the amount of regrind that can be used on each job, and that is included in a shop floor tracking sheet used by the material handlers.

Some customers request virgin material for their components when it might not be necessary. "If we have a certain family of parts that can use regrind, we'll provide the customer with samples to get their buy-in on the savings that they can realize," says McDonie. "A customer will not go through these material changes unless there's something in it for them, too."

Matthew Davidson, Xten's president, adds that typically it doesn't take a lot of educating to convince them. "Most of our customers are pretty sophisticated about their products," he says. "Even during the quoting process they'll ask us to quote the parts with a percentage of regrind. But often we'll take the initiative to go to the customer and present them with an alternative that uses regrind, particularly on large parts-they can consume a lot of regrind."

Waste not

Overall, says Davidson, Xten had a 43% reduction in total resin wasted in 2009, from 385,000 lb to 220,000 lb of scrap. A big piece of that was an 82% reduction in regrind shipped out of the building, from 220,000 lb to only 39,000 lb. Xten found ways to use all of the rest.

Another area of material savings comes at mold startup. To get a cleaner system faster, Xten looked at purging compounds. "We brought in four vendors for purging compounds and had each prove to us what its compound could do," explains Korpela. "We then picked the one that did the best job. We achieved a 25% reduction in startup waste using Unitemp's Pekutherm purging compound."

Bill Renick, Xten's VP of operations, says that Xten also cuts scrap at startup by dedicating a press for several different components that use the same material. "In the past we would bounce the molds from press to press based on what was open, and as a result we almost always had contamination at startup, which wasted material until it cleared up. Using a dedicated press for components requiring the same resin results in very little contamination. We've reduced our startup scrap over 50% just by running similar components in one press."

Davidson points out that the material used for one customer is a translucent colored ABS, where cosmetics are critical and any imperfections such as splay, poor dispersion, or any sort of contamination "just killed us."

"For another Xten customer that purchases a PP product in many different colors, our process works much better when we run the part with some regrind. The color dispersion is so poor in one particular color that we use nonconforming product from the first part of the run as regrind to get better color during the rest of the job," explains Davidson. "Overall, we've gotten so much more sophisticated in where and how we use regrind throughout the plant that we're even able to reuse our clear polycarbonates and ABS."

Recycling also includes things many shops wouldn't think about, such as spilled oil. Xten uses Sorbits recyclable absorbent towels from ITU (New Berlin, WI) to clean oil from the floor around some of its older machines as well as from technicians' hands. "We've worked with one of our oil vendors to recycle the oil and sell it back to us," says Korpela. "We're saving about $1 for every gallon we're reusing. We do the same with the hydraulic oil that we take out of the machines when we perform maintenance. We send it back to the vendor and they put in the additives to bring it back up to virgin quality, and we buy it back. It's a big cost savings to us."

Renick emphasizes that recycling oil can lead to major savings; Xten runs a lot of big machines that hold 700-800 gallons of oil each.

Returnable packaging is another program that Xten is implementing with several of its customers-some instigated by Xten and some at the request of the customer. "We have four large customers with which we currently operate returnable packaging programs," says Davidson. "The customers saved approximately $90,000 from this program last year as most of what we ship is FOB [free on board] from our plant."

Some of the shipping containers are large plastic totes that the customer buys. In other cases, Xten's customers return the corrugated boxes that are shipped to them a number of times. Davidson says that the program is turning out to be economical for Xten as well. "We have suppliers-particularly metal suppliers-that now ship their parts to us in returnable totes. That saves us over $50,000 a year."

Additionally, Renick says that one of Xten's largest customers asked it to consolidate shipments by delaying delivery until it could fill a truck, rather than shipping small amounts more often. "We saved about 600 shipments last year, resulting in freight savings of about $120,000."

Although the freight savings generally go to Xten's customers, they also benefit Xten in reducing the overall cost of doing business with the processor, keeping it competitive in a tough market.

Korpela notes that Xten is automating as much as possible by using robotics, which guarantee consistent cycle times that reduce or eliminate waste. "We're also trying to do more with robots at the press before the robot presents the part to the operator, such as clipping runners, so the robot delivers finished parts to the operator," says Korpela. "Instead of standing at the press and clipping runners or trimming parts, the operator can assemble parts and components into finished goods."

Managing inventory

Another part of Xten's sustainability program is inventory management. "For us, raw materials are not just resin or colorant," says Davidson. "We incorporate many different components such as inserts, wiring, decorations, and the like to complete the jobs we run. Many times we were forced to shut down a press or an assembly line because the customers didn't get us the component or packaging that they supplied to us. Now we try to source all the items required to make their products ourselves."

With a just-in-time (JIT) program in place, McDonie keeps Xten's inventory of resin, components, and packaging at optimum levels to ensure that jobs run smoothly from start to finish. Since the typical run time for a job at Xten averages two to three days, it becomes even more critical for the company to manage inventory well.

An additional factor to JIT inventory control is that eliminating delays, shutdowns, and subsequent restarts decreases electricity costs and startup scrap for Xten. "Startup means a big spike in electricity when you turn on the bigger presses," explains Korpela. "If you can start it up once and leave the press running without interruptions, you avoid the multiple startup spikes.

"[This year] brings us to the next layer of peeling the onion back," Korpela continues. "This includes such areas as the toolroom, where we focus on improving our preventive maintenance program. We strictly adhere to the required schedule, but any extraordinary attention may be outsourced. This allows us to stay lean on our day-to-day operation without downtime. Our machine PM program has been in place for many years and has paid great dividends in keeping our machines running. Problems are truly prevented as opposed to encountering a reactive situation."

"It is rare that downtime is caused by people," adds Renick. "First of all, we have created an environment with few absences. Secondly, all highly skilled positions are backed up. Third, our plan calls for all jobs to be cross-trained as a matter of course. Lastly, multiple work centers in our contract manufacturing environment are always in queue waiting for startup if other jobs are finished or end unexpectedly."

Web extra: Savings from major waste reduction projects Xten initiated in 2009

Material waste reduction

43% reduction in total resin wasted-from 385,000 to 220,000 lb/year

82% reduction in regrind sold-from 220,000 lb/year to 39,000 lb/year

Annual savings of $139,000

Resin

Consolidate jobs using the same material to a single press-cuts down on purging and startups; >50% waste reduction

Active use of purging compound to clean barrels with less waste; 25% reduction in startup waste

Disciplined separation of regrind by resin and color and creation of separate regrind area

Identification of jobs that can use regrind with customers' input

Corrugated

Recycling program in place: 30 tons recycled in 2009; $37,800 @ $0.63/lb = $1260/ton = $37,800/year savings

Recycle office paper; 1.5 tons recycled in 2009 = $3450/year savings

Oil

Recycle machine oil; $1/gal savings

Sorbits to gather oil for recycling; 261 lb in 2008; 362 lb in 2009; hand towels, 1754 lb in 2009 = $2100/year savings

Reducing oil leaks keeps oil in the machines

Packaging

Customer programs to use returnable packaging-eliminates requirement for new packages

• Customers: $66,000/year savings

Suppliers: Metal parts totes = $24,000/year savings

$90,000/year total savings in packaging between Xten, suppliers, and customers

Other

Freight consolidation: reduces trips/fuel/costs; $40,000/year savings ($200/trip)

Automation: consistent cycle times cut overall job waste and reduce total job time

Process improvements: reduce startup and total job time and avoid startup electrical spike

New initiatives:

Bonus programs to reduce waste: $40,000/year reduction target

Increase number of continuous runs to cut startup waste: less material used and fewer bad parts; purge reduction = $27,000 savings, parts = $10,000 savings

Kaizen cells for greater efficiency and to cut down material and time waste: $25,000 savings

Paperless office: $5000/year savings

About the Author(s)

You May Also Like