Haidlmair features foldable container molds

Austrian moldmaker Haidlmair GmbH will showcase its technology for container manufacturing that includes fruit and vegetable crates, in both rigid and foldable designs, and large sized containers, pallet boxes, and plastic pallets. The company’s specialties can be see in the West Hall, Booth #9147, including a five-component foldable crate family mold.

February 24, 2012

Austrian moldmaker Haidlmair GmbH will showcase its technology for container manufacturing that includes fruit and vegetable crates, in both rigid and foldable designs, and large sized containers, pallet boxes, and plastic pallets. The company’s specialties can be see in the West Hall, Booth #9147, including a five-component foldable crate family mold.

Haidlmair’s mold technology provides for injection molding processes that include sequential multi-color or multi-material crates and containers. Additionally, the company builds molds to accommodate in-mold labeling such as decorative foil labels on all outer surfaces during the injection molding process.

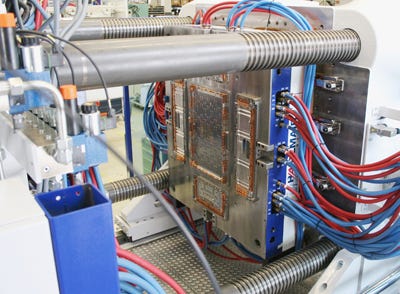

In addition to the display at its own booth, Haidlmair will be running a mold in a Wittman Battenfeld press at Booth #2843. This high-performance tool will form a stackable folding box. The returnable box for fruit and vegetable transportation measures 600 by 400 by 193 mm. All five components of the box, including the base plate and four side walls, are molded in a “family mold.”

Using this mold, Wittmann Battenfeld will be showcasing its new large machine, the MacroPower XL 850/8800 (8500 kN) with XL-sized machine plates and a distance between tiebars of 1475 by 1125 mm. These five parts of the returnable box are molded with a cycle time of 35 seconds, and after removal by a linear robot, they are automatically assembled into a finished box and stacked.

You May Also Like