K2016: Arburg launches new Hybrid Allrounder with a clamping force of 6,500 kN

October 19, 2016

Arburg used to be known as the company that made small injection molding machines. Yet, as the company has grown, so has the size of its machines. Now, the company is introducing its largest machine ever at K 2016: with a clamping force of 6,500 kN and a size 4600 injection unit, the new Hybrid Allrounder 1120 H dwarfs the other exhibits on the booth.

Arburg used to be known as the company that made small injection molding machines. Yet, as the company has grown, so has the size of its machines. Now, the company is introducing its largest machine ever at K 2016: with a clamping force of 6,500 kN and a size 4600 injection unit, the new Hybrid Allrounder 1120 H dwarfs the other exhibits on the booth.

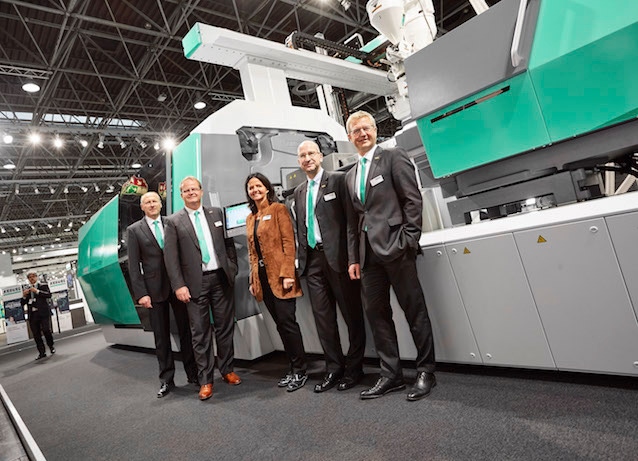

"The new Allrounder 1120 H is a response to our customers' need for large and efficient high performance machines," said Gerhard Böhm, Arburg’s managing director of sales. Which explains the new size. But what about the new design, and why a new control system?

“It’s quite simple”, said Juliana Hehl, managing partner at Arburg. “We believed that superior technology called for superior product design.” The new design, she said, serves to underscores the high quality of Arburg’s terchnology. The result is “aesthetically pleasing, dynamic and modern.”

The new design lacks the cubist build of a typical Arburg machine, inclining instead towards a more organic feel, with softened, curved lines. The color scheme has also been updated. The new design also offers enhanced functionality and improved ergonomics, such as safety doors with smooth-running linear guides, integrated fold-out steps for access to the mold area and service and sliding door for the pneumatic, electric, hydraulic, lubrication and temperature control systems, and integrated LED light strips that indicate the operating state.

The hybrid Allrounder 1120 H extends the top end of the company's products to 750 tons of clamping force, up from 500 tons and combines electric speed and precision during mold movements with hydraulic power and dynamics during injection. The toggle-type clamping unit has a dry cycle time is 2.4 seconds; the maximum opening stroke is 1,050 millimeters. The distance between tie bars, designed especially to accommodate large molds, is 1,120 mm – a 20% increase over th e closest machine in the range.

e closest machine in the range.

The new Gestica control system is based on the advantages of the familiar Selogica control system, but, said Heinz Graub, Arburgs Managing director of technology & engineering: “It’s simpler, and more intuitive.”

With the new "Easyslider" operating element, movements can be simply and precisely controlled and displayed via color-variable LED technology during set-up. Acceleration and deceleration can be controlled "with a swipe of the finger" along a bar at the edge of the screen. The data records of the new Gestica and the proven Selogica control systems are fully compatible and the hierarchical structure and graphical programming system are identical.

At K 2016, the machine is molding a 1,092 gram folding step stool designed specifically for the show and for this particular machine by the Design Tech design studio. This studio was also involved in the development of the new Allrounder. The stool parts are robotically transferred to an assembly cell, where it is finished and assembled within the injection molding cycle.

About the Author(s)

You May Also Like