Netstal to demonstrate injection compression molding on stack molds at Fakuma

At the upcoming Fakuma trade show in Friedrichshafen (Germany), Swiss injection molding machine manufacturer Netstal will be presenting what the company says is a “world first”: injection compression molding on a stack mold. Netstal will be demonstrating the new technology at its booth in hall A7 (7303/7304), where a 15oz (425g) margarine tub made from PP and weighing only 10.7 g will be molded on a hybrid Elion injection press equipped with a four-by-four stack mold.

September 14, 2015

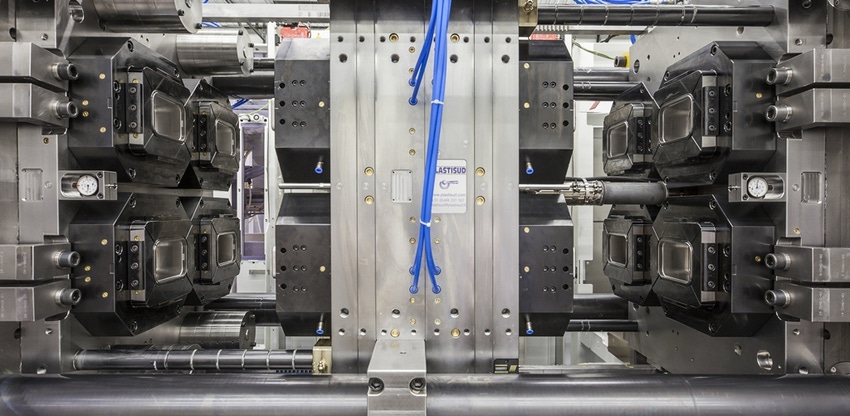

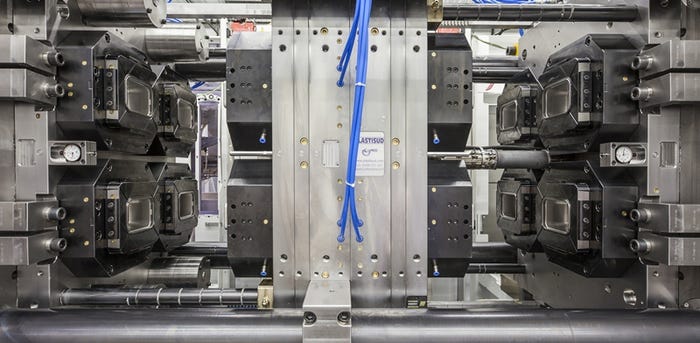

At the upcoming Fakuma trade show in Friedrichshafen (Germany), Swiss injection molding machine manufacturer Netstal will be presenting what the company says is a “world firstâ€: injection compression molding on a stack mold. Netstal will be demonstrating the new technology at its booth in hall A7 (7303/7304), where a 15oz (425g) margarine tub made from PP and weighing only 10.7 g will be molded on a hybrid Elion injection press equipped with a four-by-four stack mold. The innovative technology is the result of a collaboration between mold manufacturer Plastisud, automation specialist Machines Pagès and Netstal. While the stack mold with 4+4 cavities is impressive enough, turning out standard-sized margarine with IML decoration in a cycle time of five seconds, the truly revolutionary aspect of the whole process is hidden from view, according to Markus Dal Pian, Vice President, Sales & Marketing at Netstal.

The innovative technology is the result of a collaboration between mold manufacturer Plastisud, automation specialist Machines Pagès and Netstal. While the stack mold with 4+4 cavities is impressive enough, turning out standard-sized margarine with IML decoration in a cycle time of five seconds, the truly revolutionary aspect of the whole process is hidden from view, according to Markus Dal Pian, Vice President, Sales & Marketing at Netstal.

“The polypropylene packaging is not injection molded but manufactured in an injection compression molding process," he explained. "This combination of injection compression molding and stack mold is a complete novelty in the industrial production of packaging."

The cavities are partially filled in only 100 ms with extremely even results and the process is performed at a low pressure to prevent tension in the material. The high quality of the platen parallelism guarantees a synchronicity of 99.98 % between the mold, machine and automation system.

The stack mold, especially adapted to the requirements of the new production process, was developed in a few short months by Plastisud. The unique injection compression molding technology guarantees perfectly balanced parting planes with an extremely low dispersion rate.

"The special design of the stack mold developed by Plastisud plays a key role in this application,†Thomas Iten, PAC Application Engineer at Netstal emphasized. Machines Pagès provided specific know-how in the area of handling systems for in-mold labeling (IML) to ensure that the automation process has been adapted perfectly to the machine and mold.

According to Iten, this configuration, in which the injection compression molding process is combined with a specially balanced stack mold, is “a genuine innovative leap." The fundamental benefits of injection compression molding include narrow wall thicknesses and a lighter product resulting in lower unit costs. Furthermore, the end product (lids in particular) shows fewer signs of distortion and has a greater dimensional accuracy due to the lower stresses placed on the material.

Moreover, using a stack mold significantly increase productivity, while the technology reduces material costs by up to 20%, in addition to providing total flexibility in terms of shape, appearance and decoration of the manufactured part.

About the Author(s)

You May Also Like