Chemically Recyclable LDPE Puts Widely Used Plastic on Path to Sustainability

German researchers replicate chemical structure of low-density polyethylene (LDPE) with built-in “recycling points.”

February 23, 2024

At a Glance

- Polymer can be chemically broken into smaller fragments, which can be reused

- So-called LDPE-mimic structurally resembles commercial LDPE, commonly used in cling film and trash liners

- New material matches tensile elongation behavior and crystallization temperature of conventional LDPE

German researchers have replicated the chemical structure of low-density polyethylene (LDPE), a development that holds great promise for sustainable alternatives to one of the most widely used plastics.

A team at the University of Bayreuth led by Dr. Rhett Kempe of the Sustainable Chemistry Centre has introduced a new chemically recyclable, highly branched polyolefin material with built-in “recycling points.” That means the polymer can be chemically broken into smaller fragments soluble in organic solvents at moderate temperatures, he said. Recombining those fragments allows them to be reused.

The new material is known as LDPE-mimic and structurally closely resembles commercial LDPE, commonly used in cling film and trash liners.

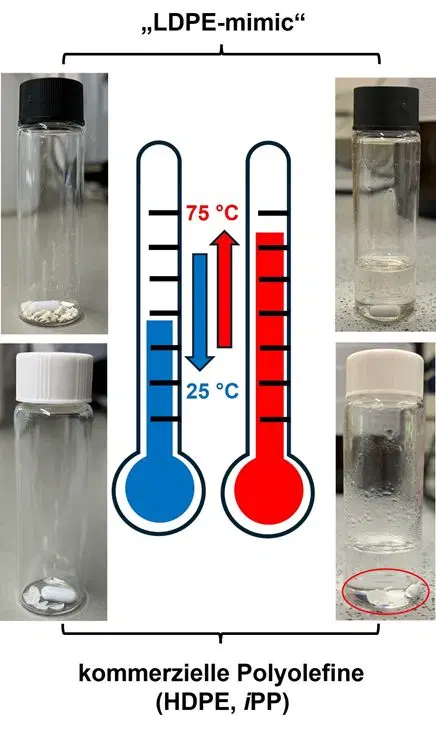

Fragments of the shredded alternative plastic (top left) compared with commercial polyolefins (bottom left). The solubility of the fragments at 75°C in organic solvents (top right), compared with other polymers (bottom right), provides a potential approach for separating plastic mixtures. Image courtesy of University of Bayreuth.

Regular LDPE is produced under extreme conditions — 250°C and 2,500 to 4,000 bar of pressure. That process is essentially to create LDPE’s highly branched, complex chemical structure.

"The key to success is the use of our new catalysts, which produce defined building blocks of a certain size under correspondingly mild reaction conditions, around 70°C and 2 bar pressure,” Kempe explained. “These can then be combined to form the final plastic material.”

Specifically, he continued, "the new material consists of two different macromonomers — a backbone and potential long-chain branches. The branches can be reversibly attached to the backbone and cleaved under acidic and basic conditions."

The structure and properties of the LDPE-mimic match key elements of the real thing, including tensile elongation behavior and crystallization temperature.

“The tensile elongation behavior of our LDPE mimic P4 is similar to commercial LDPE and shows a similar elongation at break, with a slightly different tensile strength,” according to the researchers’ published results. “TGA and tensile tests of the recycled polymer are close to the data of the original polymer. Significant cross-linking of our mimic is observed at 170°C.”

The research team has published its report, “A Closed-Loop Recyclable Low-Density Polyethylene,” in the journal Advanced Science.

About the Author(s)

You May Also Like