Covestro Launches Bio-based Aniline Pilot Plant

In what it’s calling a world first, Covestro will produce a 100% plant-based version of aniline, which is used to make MDI, a component of insulating foam.

February 14, 2024

At a Glance

- Until now, aniline has been produced from fossil-fuel-based materials

- Bio-based aniline will be used to make MDI, part of insulating foam in buildings and refrigerators

- Global aniline volume is projected to grow 3% to 5% annually

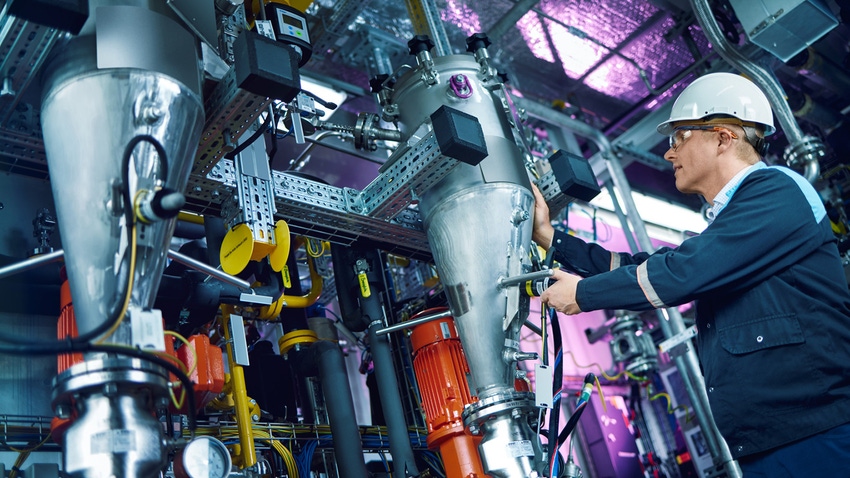

Plastics maker Covestro is making a big bet on circularity by opening a pilot plant to produce bio-based aniline, a chemical essential to the production of insulating foam.

The plant, at Chempark Leverkusen in North Rhine-Westphalia, Germany, will develop and produce the 100% plant-based version of aniline as a precursor to progressing to industrial scale. In the process, a custom micro-organism converts sugar from plants into an intermediate product through fermentation under environmentally friendly mild conditions. Chemical catalysis then converts the intermediate product into aniline.

“Until now, aniline has been produced from fossil raw materials such as petroleum, which releases CO2 and fuels climate change,” explained Dr. Thorsten Dreier, chief technology officer of Covestro. ”With our new process, we are contributing to building up a circular, bio-based economy, and I am very proud that we have now succeeded in making the jump to the next technological level.”

Aniline is used to make MDI, a component of insulating foam used in buildings and refrigerators. Covestro contributes more than one million tons of the six million tons of aniline produced annually around the world. Global aniline volume is projected to grow 3% to 5% a year.

"Sustainable innovations from North Rhine-Westphalia are making a decisive contribution to the transformation of Germany as a chemical location,” said North-Rhine Westphalia’s Deputy Minister President Mona Neubaur, who is also the State Minister for Economic Affairs, Industry, Climate Protection and Energy. “The world's first pilot plant for bio-based aniline is an impressive example of this. In order for the industry to continue on its path toward a circular economy and climate neutrality, it needs planning and investment security above all. As the state government, we are therefore working hard to ensure that North Rhine-Westphalia remains an attractive business location and becomes the first climate-neutral industrial region in Europe."

The project, funded by the German government, also includes partners RWTH Aachen, the CAT Catalytic Center, and the University of Stuttgart. A follow-up project that started in March 2022 runs until 2025.

About the Author(s)

You May Also Like