August 20, 2002

|

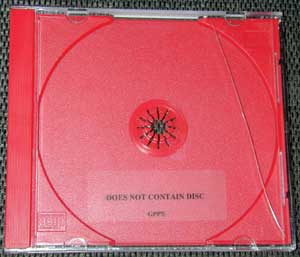

Colored CD jewel cases (left) were molded from GPPS and mailed to IMM. Clear cases (right) were molded from K-Resin. |

|

All boxes arrived undamaged, except for one GPPS case.

|

Eddie Edmunds, K-Resin marketing director for Chevron Phillips Chemical Co., hatched an ingenious plan while looking for a way to demonstrate the toughness of

K-Resin SBC. He decided to produce molded CD jewel box cases using four different grades of the material, and then mail the cases to various Chevron Phillips employees in offices around the world.

Each trip the cases made would be documented by the recipient, and their condition noted. The experiment would include traditional PS cases as well for comparison purposes, and all would be marked with colored dots to indicate which of the five materials they contained. All of the cases would be molded by the same Chicago-area molder.

Just to make the conditions more extreme, Edmunds began his mailing campaign on December 21, 1999 as postal services around the globe were getting hit with the holiday rush. He even requested rough treatment from his local post office, and the clerks complied by tossing CD cases into bins with wild abandon.

Each recipient on the list (below) received a total of 25 jewel cases that were individually shrink-wrapped. Single cases were dropped at local post offices and postal drop boxes on consecutive days to avoid bundling by the postal services. "The whole idea," says Edmunds, "was to have the cases exposed to extreme handling, so we went out of our way to ensure that."

Of course, there were plenty of anecdotal stories to tell—an entire shipment lost in Mexico, cases held up in Frankfurt by suspicious customs officials, mysterious notes written in French on boxes that were routed to Germany. But when all was said and done, the K-Resin grades withstood the mailing process without cracking, with two exceptions, one in Singapore and one in Germany. The general purpose PS cases logged damage about a third of the time. Of the four grades tested—KR01, BK13, a blend of 75 percent BK10 and 25 percent NAS21, and a blend of 75 percent KR03 and 25 percent NAS21—all appeared to perform equally well in this application.

IMM attempted to reproduce the experiment by having 10 CD cases sent to one of its editors. Conditions were not exactly replicated, however, as the holiday season had passed and the cases were making only one trip. In this instance, only one of the 10 GPPS cases cracked, while none of the 10 K-Resin cases sustained any damage.

Edmunds admits that with the price for CD jewel boxes at $.07 to $.08 each, K-Resin at $.90/lb will have trouble competing with GPPS at $.30/lb. However, he does see a probable market in CD case mailers (no corrugated paper packaging required and a significant reduction in postage and shipping and handling cost) or cases for audiophiles seeking a better way to store CDs. "Even if this application never materializes, we feel the experiment was indeed a success in demonstrating the toughness of K-Resin SBC," Edmunds says.

Chevron Phillips Chemical Co. LP

The Woodlands, TX

(832) 813-4100

www.cpchem.com

You May Also Like