High Tensile Modulus Carbon Fiber Matches with Thermoplastic Pellets

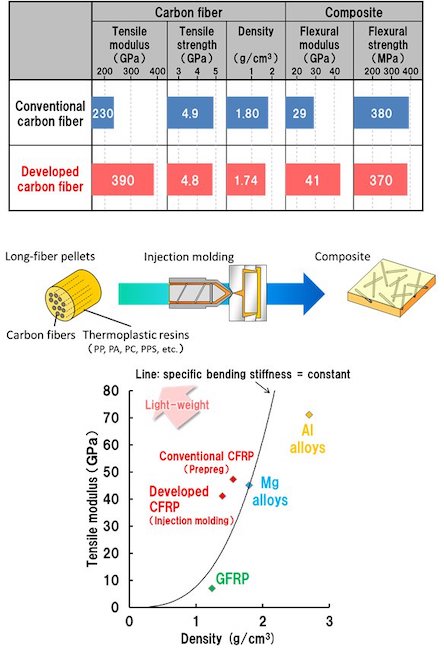

Toray’s new carbon fiber elevates reinforced thermoplastic composite performance to the realm of thermoplastic composites and magnesium alloys.

May 26, 2020

Toray Industries has created a high tensile modulus carbon fiber and thermoplastic pellets that are ideal for injection molding employing the said fiber. The pellets will reportedly enable the efficient production of complex, rigid parts that are also light, thereby lowering environmental impact. These advances could greatly enhance cost performance according to Toray. The company will push ahead with research and development to commercialize the fiber and pellets within the next three years.

Toray markets the Torayca T series of high-strength carbon fibers for pressure vessel, automotive, and other industrial applications, as well as for aerospace. In 2014, it launched Torayca T1100 carbon fiber, which offers a world-leading tensile strength of 7.0 GPa and a tensile modulus of elasticity of 320 GPa.

|

Toray’s new carbon fiber elevates reinforced thermoplastic composite performance to the realm of thermoplastic composites and magnesium alloys. Image courtesy of Toray. |

In 2018, the company further expanded the potential of carbon fiber for high-end sports equipment and aerospace structural materials by commercializing Torayca M40X. This offering employs proprietary nano-level fiber structure control technology to balance a high compression strength and a tensile strength of 5.7 GPa, with a tensile modulus of 377 GPa. The fiber’s diameter of 5 microns constrains productivity, however, making costs an issue.

In the most recent development effort, Toray tackled that challenge by pursuing further advances with its Torayca MX series control technology to create 7-micron fibers with uniform internal structures. The result was a fiber with a tensile modulus of elasticity of 390 GPa, around 70% higher than the standard level of Torayca series offerings for industrial applications, delivering a much better cost performance.

Torayca thermoplastic pellets incorporating the newly developed carbon fibers maintain longer fibers than conventional high tensile modulus offerings after molding processes. The pellets can thus deliver attain a tensile modulus of 41 GPa. That is comparable to the 45 GPa of magnesium alloys. At the same time pellets have a specific gravity of just 1.4, against the 1.8 of magnesium alloy. Using these pellets to make complex parts through injection molding processes would significantly enhance productivity and contribute much to lightening parts.

Toray is looking to cultivate diverse applications for its advanced pellets, including for parts in lightweight next-generation automobiles and in industry in general.

About the Author(s)

You May Also Like