Material Innovations at K 2022

Titanium dioxide–free white masterbatches, grades optimized for laser welding, and a new silicone additive for PE compounding are in the spotlight.

October 6, 2022

From a new range of white masterbatches to formulations optimized for laser welding, material innovations will be in abundance at K 2022 in Düsseldorf, Germany, from Oct. 19 to 26.

Masterbatch improves filler distribution, flow properties

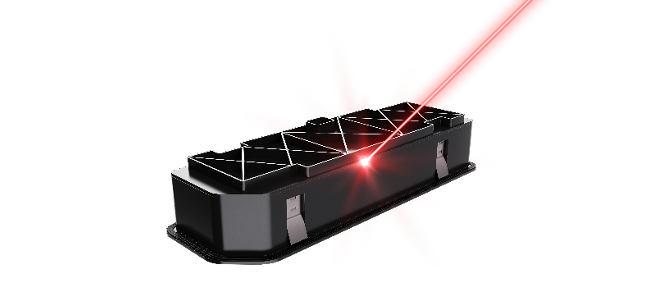

Germany’s Wacker will spotlight several additive masterbatches for thermoplastic compounding, including its new Genioplast PE50S08 silicone product for PE compounding, pictured above.

Whether used in applications involving film extrusion or processing recycled PE compounds, Genioplast PE50S08 also improves the surface properties of the final plastic products, the company said. Dosage is 1% to 3%, and it’s easy to incorporate in PE mixtures on twin-screw extruders, even when mineral fillers are added.

With silicone content of 50%, the pellet-form masterbatch is an active component containing a nonreactive, ultra-high-molecular polydimethylsiloxane. Low-density PE carries the active ingredient.

As a processing aid, Genioplast PE50S08 improves filler distribution and flow properties, the company added, ultimately increasing extruder throughput while reducing energy usage.

And for PE recycling, Wacker’s new masterbatch ensures uniform mixing of different PE grades without significant fluctuations in torque or temperature.

Wacker will also highlight:

Genioplast Pellet S for compounding all thermoplastics. It contains a non-crosslinked ultra-high-molecular silicone polymer mounted on pyrogenic silica. Its main application area is flame-resistant cable sheathing.

Genioplast PP50S12 for improving scratch resistance of PP products, primarily packaging films, garden furniture, and car interior components.

Genioplast Pellet 345 for thermoplastic polyurethanes, which imparts a pleasant feel to smartphone covers, wearable armbands, and other items while increasing dirt resistance.

Wacker will exhibit in Hall 6, Booth A10.

New PBT grades optimize laser welding for auto parts

To speed production of automotive parts, DuPont Mobility & Materials has launched three new grades of its Crastin PBT materials optimized for laser welding.

Now commercially available, Crastin PBT materials are engineered to allow a balance between level of laser transmission, low warpage, hydrolysis, and chemical resistance. One grade improves laser transmission up to 200%, the company said. They join DuPont’s Zytel polyamide laser-welding solutions.

|

Crastin PBT materials feature improved laser transmission as well as hydrolysis resistance, according to DuPont. |

Laser joining is favored for automotive, medical, and electronics applications because it does not heat or vibrate sensitive materials and joins quickly without creating particulate. For the automotive industry, Crastin PBT materials will improve the performance of connectors, sensors, ADAS systems, and other sensitive electrical components.

“Until now, conventional solutions for laser welding have low levels of hydrolysis resistance,” said Miles Wang, Application Development Director for DuPont Mobility & Materials. “Our new solutions improve laser transmission as well as other properties such as hydrolysis resistance.”

DuPont Mobility & Materials will exhibit in hall 6, stand C43.

TiO2-free masterbatches address EU ban

A new series of white masterbatches that do not contain titanium dioxide (TiO2) will be on display courtesy of Israel’s Tosaf. Tosaf created the product to address concerns over the potentially carcinogenic nature of the material in powder form, as well as the EU ban of TiO2 as a food colorant.

|

The non-TiO2 white masterbatches are compatible with all polymers, according to Tosaf. |

With more manufacturers, including those in the packaging, toy, and cosmetics sectors, seeking non-TiO2 alternatives, Tosaf offers a range of solutions featuring cylindrical or spherical granules. The company said its formulations perform on par with those containing unbound titanium dioxide, exhibiting strong color and an equal let-down rate.

Tosaf’s new non-TiO2 white masterbatches can be tuned from yellowish to neutral to bluish, the company added, and are compatible with “any host polymer.” The materials also preserve tool life thanks to low abrasiveness. Users will experience no plate-out when processing on two-roll systems, the company added.

Tosaf will exhibit in hall 8a, booth D01.

About the Author(s)

You May Also Like