Real wood feel, function in a wood polymer composite

"Fully fibrous" is how Eovations describes its wood polymer composite (WPC) product, a technology that originated at a British polymer research institution and was a Dow Chemical project at one time. The patented process results in a composite profile that "replicates the fibrous structure of wood and creates a unique combination of strength, durability, aesthetic and workability properties," according to company information.

April 15, 2013

"Fully fibrous" is how Eovations describes its wood polymer composite (WPC) product, a technology that originated at a British polymer research institution and was a Dow Chemical project at one time. The patented process results in a composite profile that "replicates the fibrous structure of wood and creates a unique combination of strength, durability, aesthetic and workability properties," according to company information.

Dick McBride, general manager of operations at Universal Forest Products Inc., which is Eovations' parent company, told PlasticsToday that the company already has some commercial applications applying the technology. These include siding and trim, produced in Selma, AL, as well as OEM door components.

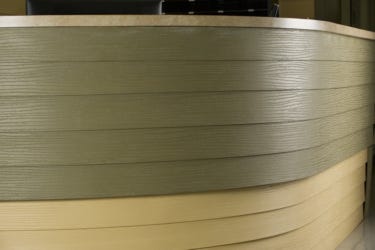

Eovations extrusion |

Eovations embossing. |

Eovations profile |

At this point, the company is both selling technology licenses and making composite components itself. McBride said there are currently no licensees, but added that, "A number of companies have expressed interest in the technology, and we continue discussions with many prospective licensees in a range of industries."

The technology was originally developed by Dow, in collaboration with the Polymer IRC at the University of Bradford in Britain. Ownership was transferred to Eovations in early 2010. At NPE 2012, extrusion technology supplier battenfeld-cincinnati announced plans to collaborate with Eovations on commercializing the technology.

McBride said the company has multiple patents for the technology, including ones covering process, formulation, and applications.

Eovations promotes the fully fiberized thermoplastic-mineral composite as a candidate to replace wood, wood-plastic composite, plastic, and metal in a wide range of structural and nonstructural applications. Key appeal to the product: its similarity to natural wood. "The material can be machined, milled, cut and drilled using basic carpentry skills and common woodworking tools," Claude Brown, Eovations VP of Technology & Innovation said in a release. "Fastener acceptance and hold is excellent using conventional nails, screws and staples. Variations of the composite readily accept common paints."

About the Author(s)

You May Also Like